Wind turbine technician jobs are growing, and new schools are popping up to provide training.

In the U.S., wind tech jobs are expected to grow by 96% by 2026, according to the Bureau of Labor Statistics. Also known as tower techs and a multitude of other similar names, they fall under the large umbrella of an estimated 105,000 wind energy workers including positions in project development, component manufacturing, construction operations, education, training and research.

The continuous growth has been fueled by tax incentives encouraging wind tower construction and a growing interest in lowering costs associated with renewable energy. Additionally, many more wind turbine technician training programs, both in the U.S. and around the world, are springing up including trade schools, in-house training, community colleges, privately funded schools and state funded ones like those found in New Mexico, as well as the formation of standardized training organizations such as the Global Wind Organization (GWO).

In U.S. News and World Report's 100 Best Jobs 2018 survey, wind turbine technicians held the #41 spot based on salary: low - $43,590, medium - $52,260, high - $62,720; education needed; work-life balance and job satisfaction.

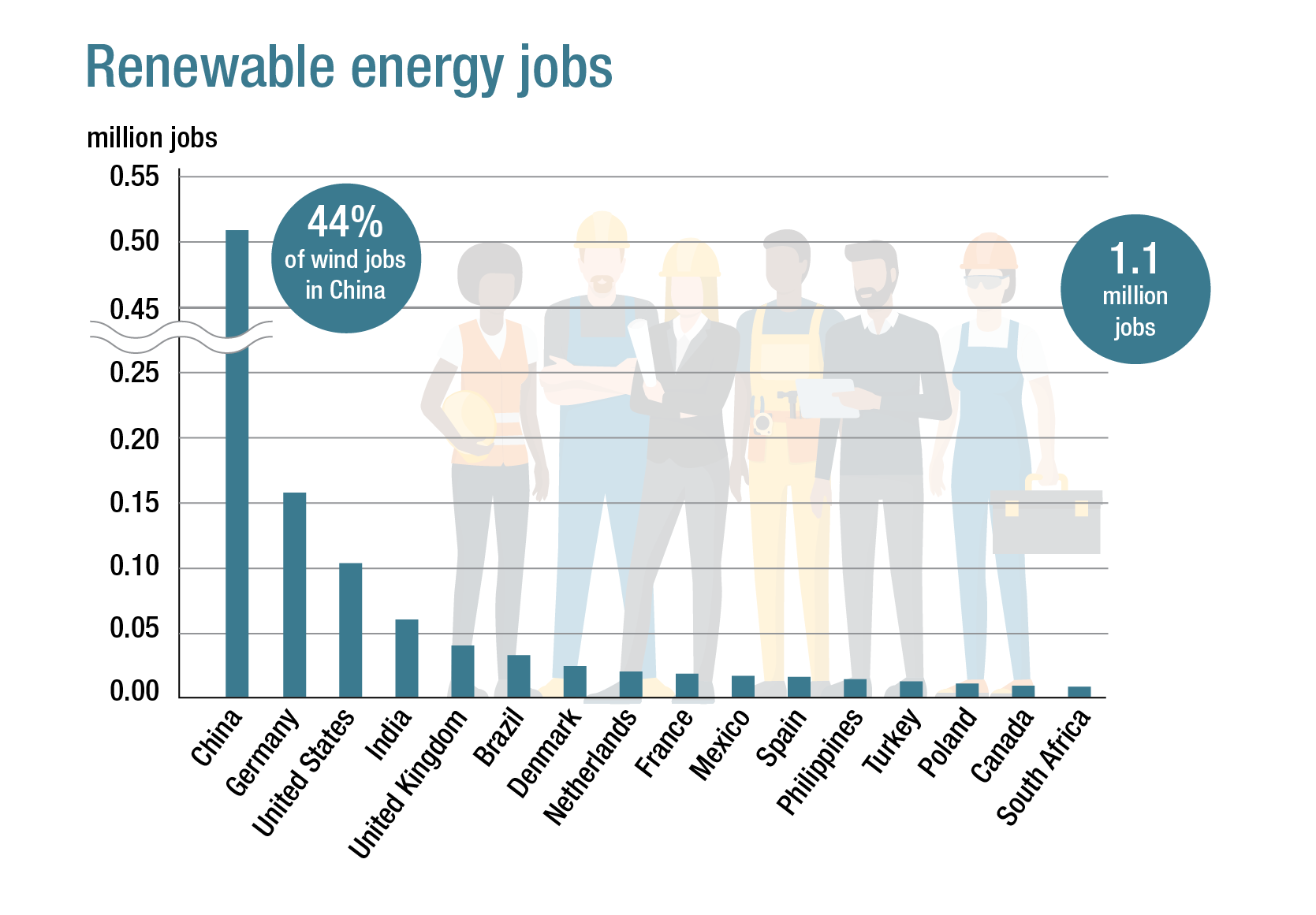

Renewable energy global growth

As reported by the International Renewable Energy Agency (IRENA), China represents 44% of wind employment, followed by Europe at 30% and North America at 10%. The largest installations of wind energy capacity exist in Europe.

Although jobs in wind energy declined, according to the IRENA 2018 Renewable Energy and Jobs Annual Review, when you compare global year-to-year growth, wind energy jobs have increased noticeably from 2012 to 2017.

As wind turbine heights grow, so does the demand for wind techs

As the wind energy industry has grown, so has the size of wind towers, because higher towers catch more wind and therefore generate more power. Also, with the aging of older wind towers and the construction of newer, bigger and more technologically-advanced ones, repair and maintenance issues have become more complex and therefore the need for higher-level training of wind technicians.

O.Net, a primary source for finding occupational information and data, lists the top five general skills a wind tech needs includes repairing and troubleshooting, equipment maintenance, critical thinking and operation monitoring. Wind techs also need to know how to diagnose, detect, test, analyze and use various software systems and tools.

Top five wind tech tasks performed, and tools and software used

| TOP FIVE | Tasks | Tools | Software |

|---|---|---|---|

| 1. | Diagnose problems with wind turbine generators or control systems | High voltage cable detection — hot stick | Analytical or scientific software - computerized diagnostic software |

| 2. | Climb wind turbine towers to inspect, maintain and repair equipment | Lubricant oil sampling kits | Electronic mail software - Microsoft Outlook |

| 3. | Test wind system electrical components using voltage testers, multimeters, oscilloscopes, infrared testers and fiber optic equipment | Digital multimeters | Enterprise resource planning ERP software - SAP |

| 4. | Start or restart wind turbine generator systems to ensure proper operations | Signal generators | Facilities management software - computerized maintenance management system (CMMS) |

| 5. | Troubleshoot and repair mechanical, hydraulic and electrical malfunctions related to variable pitch, speed control and converter systems | Stripping tools | Industrial control software - industrial control systems software; programmable logic controller, SCADA software |

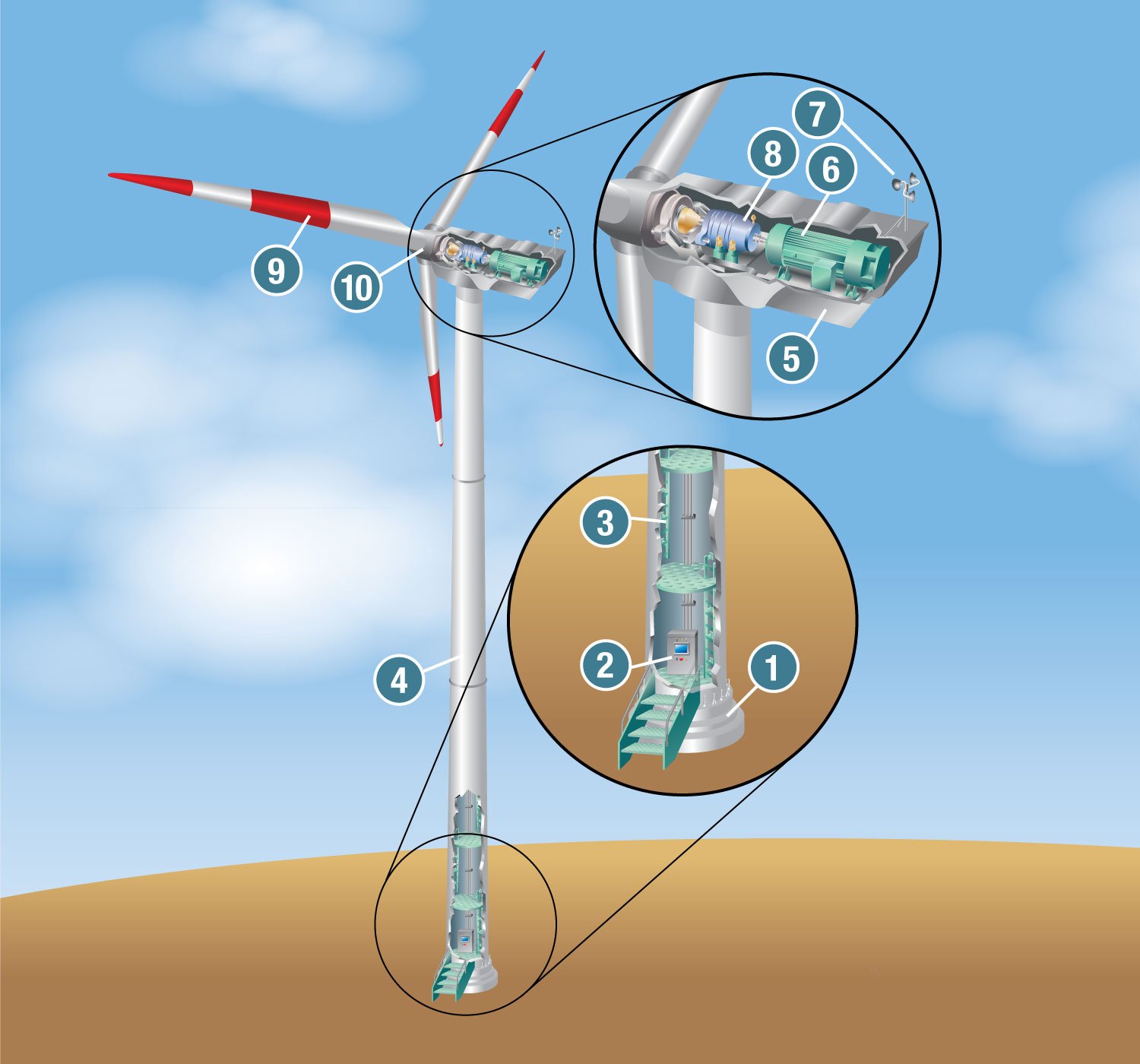

A tower tech's job is to maintain the equipment usually located inside the wind tower and includes greasing the blade, generator, main and yaw bearings, changing out filters, replacing carbon brushes, torquing all bolts, and performing dozens of electrical checks and tests often using the Fluke 87V industrial multimeter.

Safety is of paramount importance and harnesses, lanyards, climb assists and elevators are all part of the job, as well as feeling comfortable with heights and being physically fit. Usually, each tech is assigned around 10 towers and many will name their towers because of the amount of time they spend with them. Even though climb-assists and elevators are often there to help them ascend and descend in the tower, techs still need extra physical strength because of the constant demand to go up and down multiple times in a day, month or year to keep each tower fully maintained.

More complex problems can be hard to diagnose

Tower techs must also be able to inspect, adjust, diagnose and repair what are sometimes complex electrical, mechanical and hydraulic faults. The wind industry is still fairly new and solutions to wind tower issues aren't always obvious. Finding the exact problem can sometimes be time consuming and frustrating. When faced with more complex problems, a resource technician may step in to help find the problem.

Joshua Steinke is a Resource Technician II for Vestas and focuses mainly on repairs and commissioning and operates as more of a field engineer troubleshooting more complicated issues.

"Most new towers communicate information using fiber optics, such as relaying safety system data to ensure a worker stays safe while troubleshooting," said Joshua. "The tower talks to itself all over via the fiber optic cables, but it also relays mechanical information about, for instance a wind change that a sensor picks up. Signals move from module to module and once it gets to the yaw, a command is made to move the nacelle into the wind and adjust blade pitch as needed."

"When tracing down circuits, we generally use the Fluke 289," says Joshua. "We also use Fluke tools for phase rotation to indicate rotary field and motor rotation, but also their fiber optic scope to test cables. We really love the scope for checking for damage and dirt and determining how much we need to clean the cables."

Talk to an expert about Fluke’s wind energy tools and solutions

In general, when people see a wind turbine tower, they only think about the turning blade, not about how it keeps turning and the wide range of components inside the structure. As wind towers continue to grow in popularity, number, size and sophistication, so will the value and demand for a skilled wind turbine technician. Find out how Fluke is supporting the burgeoning wind energy industry with rugged, reliable and safe tools. Talk to Fluke experts about finding the right suite of tools to help you troubleshoot wind turbine problems.