Properly functioning cooling tubes are critical to keeping transformers from overheating. Transformers are especially susceptible to overheating because as they step up or step down voltage levels between circuits, energy is lost as heat in the core and windings. That heat can build up damaging insulation and leading to transformer failure.

A safe and easy way to ensure that cooling tubes are effectively dissipating that heat is to inspect them using a thermal camera.

Cooling tubes on oil-filled electrical equipment operate on the simple principle of convective cooling. As the oil circulates around the transformer’s internal windings it increases in temperature and decreases in density. The warmer, less dense, and thus, lighter oil tends to rise. As the oil cools, it becomes denser and tends to sink, which produces a natural circulation cycle.

How to tell if your cooling tubes are running hot

Thermal cameras are ideal for inspecting cooling tubes banks because they’re usually several feet tall and several inches wide which provides a large surface area. This makes it easier to gain line of sight access to so you can scan them with a thermal camera from well outside the hazard zone.

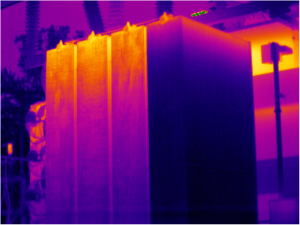

In the image shown here, the three banks of cooling tubes on the left display what is considered a normal thermal pattern. The fourth bank of tubes on the right has an abnormal pattern. Oil isn’t circulating in the fourth bank of tubes. This could be caused by:

- Not enough oil in the system

- A flow obstruction or a closed valve

- Out-of-level equipment

What to do with a hot cooling tube

Regardless of the cause, an abnormal thermal pattern in cooling tubes must be reported and escalated for further troubleshooting. If left alone, the cooling capacity of the tubes will be reduced, which can cause significant damage to the transformer. If you capture this type of thermal pattern with your thermal camera, you should report it immediately so it can be addressed before it becomes more critical.