Flat roof membranes are the waterproof barriers between the outside elements and the interior of buildings. They come in a variety of materials and designs. They must be able to expand and contract, resist high winds and the effects of solar radiation and withstand foot traffic. It is easy to see why roofs leak.

Normally there is little or no water within a flat roof assembly. When a leak develops, water enters the assembly and, depending on the type of insulation system, is either absorbed by the insulation or runs to the cracks between the nonabsorbent insulation. When water enters the roof assembly it is there for a long time, sometimes the life of the roof.

Thermal capacitance is the physical property of a material's ability to store heat. The materials in roof assemblies have relatively low thermal capacitance, especially when compared to water. Water requires a lot of energy to raise its temperature and likewise must release a lot of energy to cool.

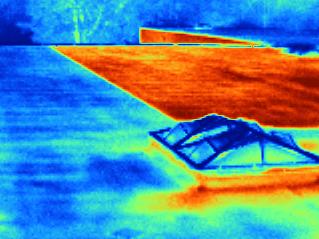

The physics used for thermal roof inspections is that dry roof insulation heats up and cools down faster than wet roof insulation. Infrared inspection goes beyond simply finding a leak by locating the extent of the moisture invasion of the insulation. To do this we require solar heating of a sunny day. Then at night, after the sun goes down and the roof surface begins to cool, the dry roof insulation cools faster than wet roof insulation. This temperature difference can be detected by the IR-InSight® and FlexCam®S.

Best conditions to perform thermal imaging inspections

In order to obtain high quality infrared images, it is necessary to perform thermal imaging roofing inspections under the right conditions. We require a different temperature between the day and night. For best results, here are some things to consider:

- Was it a clear sunny day?

- Is it a clear night (for good radiation cooling)?

- Is there little or no wind?

- Is the roof surface dry?

- Is the roof clear of snow, dirt and debris?

The type of insulation used on a roof will result in an infrared image that is characteristic of how that particular insulation absorbs water. Absorbent roof insulation acts similar to a sponge. The water migrates by capillary action throughout a complete roof board before it jumps to the adjacent board. This results in a checker board thermal pattern.

Nonabsorbent roof insulation creates a much different pattern when it becomes wet. The water is not absorbed and runs to the edge of the roof board. The water tends to collect at the edges of the boards resulting in a window frame pattern. Different patterns may result from other less common insulating systems.

There are many conditions that can produce thermal patterns that may look like they were created by wet insulation but are not, and others may mask the true condition of wet insulation. The ASTM specification C-1153 titled "Location of Wet Insulation in Roofing Systems Using Infrared Imaging" suggest performing verification of suspected wet insulation by core methods. The following are some examples of situations that may result in poor infrared inspections:

- Insulation with different R-values or different absorption characteristics which are commonly found in repaired areas.

- Different internal building temperatures.

- Extra gravel or bituminous left from construction.

- Warm or cold air exhausting onto roof.

- Re-radiation of heat from south or west facing walls.

- Wind.

- Internal sources of heat or cold such as lights, heaters, and steam pipes.

- Dirt, vegetation and debris.

- Walkway pads and buried steel plates.

- Blisters.

- Water ponding, steam plumes and water spray.

During the winter use the same process; however, winter surveys are more difficult because the temperature differences are usually less than on summer surveys (5F vs. 20F). If the building is heated, the added heat flow from the building through wet insulation will help enhance the winter thermal patterns.

Some safety reminders are:

- Do not work on a roof alone.

- Don't walk backwards on a roof.

- Follow company and government safety regulations.