The digital multimeter is the mainstay of electrical troubleshooting and the tool that most of us reach for first. In Beyond the Multimeter, we look at five examples of how reaching for an oscilloscope next can make troubleshooting faster, easier, and more effective.

Part 2 describes troubleshooting transient reflections in the pulse-width-modulated output of variable frequency drives (VFDs).

Are Reflections Causing Motor Winding Damage?

Variable frequency drives control the speed of machinery and processes by varying the width of ("modulating") the voltage pulses they send to motors. These voltage pulses (which are essentially square waves) have fast-rising edges that can cause transient voltage reflections ("transients") in the cable between the VFD and the motor. Many factors affect the size of the reflected waves, including cable length, motor load, the surge impedance of the cable and motor, and the rise time, spacing, and magnitude of the drive pulses.

Over time, these reflected wave voltages can place too much stress on cable and motor insulation, which can cause either to fail.

Troubleshooting with a Multimeter

Making voltage measurements using a digital multimeter can reveal excessive voltage at the motor terminals when transients are present.

To check the voltage, connect the multimeter at the motor terminals between phases L1, L2, or L3.

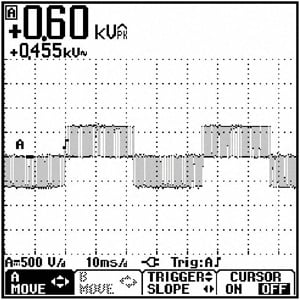

The value shown on the multimeter in Figure 1 is the peak voltage of a VFD and motor combination with no reflections.

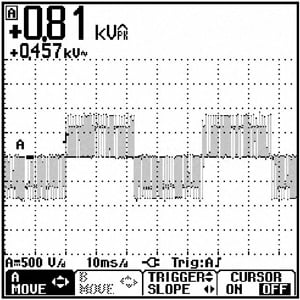

A higher than normal reading in Figure 2 indicates the effects of reflections.

You can use a digital multimeter to measure the peak voltage of a PWM signal. However, the limited bandwidth of the typical multimeter makes measuring pulses with short rise times problematic, so the readings may not provide the complete picture of the presence - or full amplitude - of any reflections or transients. And even the best digital multimeter can't show you what the waveforms actually look like.

In Figure 2, when you check the peak PWM voltage applied to the motor, it's unclear how close the transient peaks are to the maximum rating of the motor or if the motor insulation is in danger of breaking down. You need more information.

Troubleshooting with an Oscilloscope

Oscilloscopes display a signal as a line that moves across the screen from left to right. The higher the voltage, the higher the signal appears on the oscilloscope screen. Measurements made with an oscilloscope reveal not only the presence of excessive voltage at the motor terminals, but gives you a clear picture of size, location, and duration of any voltage transients.

To take a reading, connect the scope to the motor terminals between phases L1, L2, or L3, just as with the multimeter in the previous example.

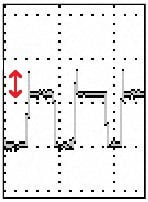

Figure 3 shows an ideal PWM signal with normal peak voltage.

Figures 4 and 5 show high-voltage transients caused by voltage reflections. Compare the waveform of the signal where the effects of reflections create high-voltage transients to the waveform of a signal without transients in Figure 3.

Voltage reflections are often caused by improper cabling. An oscilloscope with a wide bandwidth and fast sampling rate can accurately capture peak voltages caused by cable reflections.

The Bottom Line

A digital multimeter can help you discover excessive voltage on a drive signal, but an oscilloscope can show you the actual waveforms, enabling you to see whether the signal is healthy or if it has harmful transients. A handheld oscilloscope makes it easy to make the measurements where you need to make them.

A picture really is worth a thousand words!

- Beyond the Multimeter, Part 1: Troubleshooting a Variable Frequency Drive with a Multimeter and an Oscilloscope

- Beyond the Multimeter, Part 3: Troubleshooting a Rotary Encoder with a Multimeter and an Oscilloscope

- Beyond the Multimeter, Part 4: Troubleshooting a Proximity Switch with a Multimeter and an Oscilloscope

- Beyond the Multimeter, Part 5: Troubleshooting a DC Power Supply with a Multimeter and an Oscilloscope