Ever find yourself in a tangle of heavy conductors and decide to use a clamp meter's jaws as a lever to separate them? You would not be the first.

Recognizing that technicians routinely face tough work environments, Fluke engineers its clamp meters to withstand a high degree of unconventional use—as a wedge, makeshift pliers, nutcracker, whatever a tech might dream up in a moment of need.

Manufacturers, of course, prefer that techs avoid using their clamp meters as door jams or panel-door pry bars. Still, moments of desperation often lead to wacky applications, so Fluke has made product durability a brand pillar. In clamp meter lab tests, Fluke jaws have stood up to the torque generated by a 5/8-inch rod, suggesting that Fluke clamps are equipped to handle real-world job-site demands.

"When you talk about ruggedness, it's more than just dropping the unit and expecting it to work," says Terry Morey, head of the Fluke mechanical engineering department. "It's how well does the ink stay on the buttons? How well does the snap on the battery door last? If the product vibrates a lot, would the battery still make connection? The list goes on and on."

"Every part is a 'product' we have to think about," says Fluke senior mechanical engineer Brian Aikins. "We are constantly asking ourselves, 'How does this part affect the overall product performance?' "

"We see good mechanical design as extremely valuable to the customers, but it's kind of hidden," Morey says. "And we put a lot of engineering time into making sure the product we design is safe as well as robust."

For instance, tools used to measure up to 1000 volts must meet "creepage and clearance" specs to separate a user's hand from the electricity inside the meter. The halves of most Fluke multimeters come together in complex interlocking joints that provide nearly an inch of creepage and clearance separation.

"We spend hours and hours looking at that," says Morey. "It's not just a straight shot, it's three-dimensional."

So considering a manufacturer's reputation for quality construction is an important factor to ponder when evaluating clamp meters. In addition, look for these attributes:

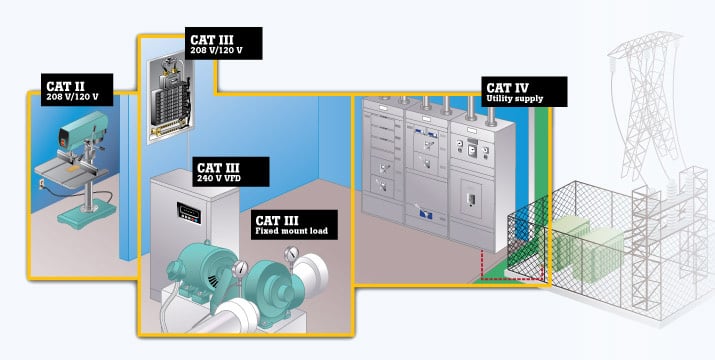

Appropriate CAT ratings: Dependable clamp meters include a CAT rating—a category and voltage rating issued by the Switzerland-based International Electrotechnical Commission. The IEC establishes international safety and quality standards for electronic products.

For electrical measurement products, a CAT rating indicates the meter's input circuitry has been designed to withstand voltage transients commonly found in one of three electrical environments without harming the user (see diagram below). If, for instance, you need to make measurements in an electrical panel with 480 V, you'll need a meter rated CAT III-600 V or CAT III-1000 V. The test probes you use with the meter should have an equal or greater CAT rating.

A clamp meter's CAT rating is usually displayed near its input jacks. Clamp meters that are not CAT-rated should never be used in high-energy, three-phase electrical work environments.

Make certain your test tool category rating matches how you are using it, even if that means regularly switching meters. Or, invest in a CAT IV-rated meter and use it exclusively, eliminating the need to question the CAT level of each measurement.

| Measurement Category | Description | Examples |

|---|---|---|

| CAT IV | Three-phase at utility connection, any outdoor conductors. Limited only by the utility transformer feeding the circuit. >50kA short circuit current. |

|

| CAT III | Three-phase distribution, including single-phase commercial lighting. <50kA short circuit current. |

|

| CAT II | Single-phase receptacle connected loads. <10kA short circuit current |

|

| Measurement Categories IAW IEC/EN 61010-031 | ||

Independent verification: While the IEC develops and proposes standards, it is not a regulatory agency and does not enforce standards. So it's wise to look for the symbol and listing number of an independent testing lab such as Underwriters Laboratories (UL), Canadian Standards Association (CSA Group), and Germany's TÜV Rheinland or VDE. Their symbols can only be used if the product successfully completed testing according to the agency's standard, based on national/international guidelines.