The arc flash boundary is the minimum “safe” distance from exposed energized conductors or circuit parts that has the potential for an arc flash. Arc fault incidents happen daily in the United States. Take the proper steps to ensure your safety before taking any measurements, especially on energized equipment. Know where the arc flash boundaries are and keep these top safety measures in mind.

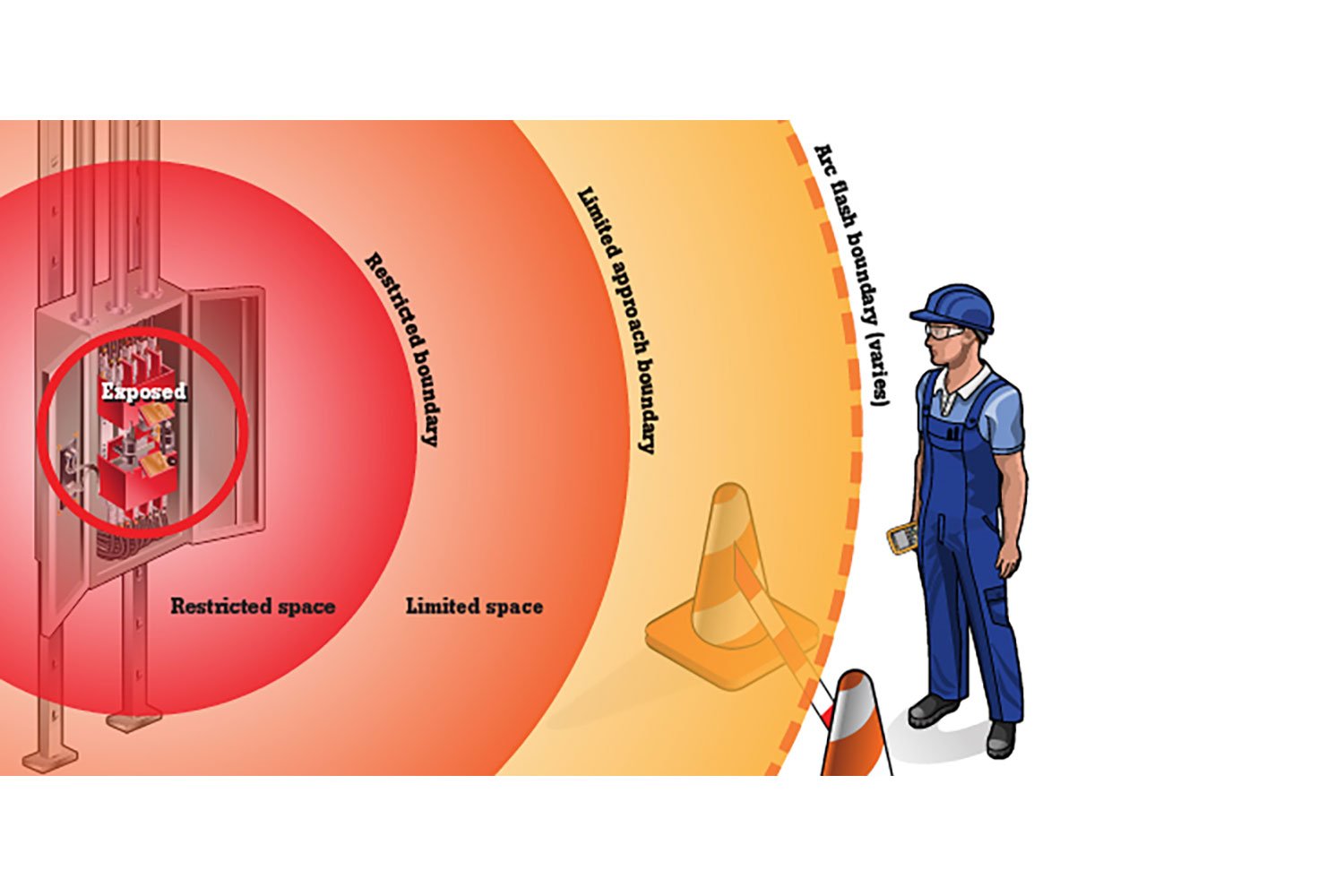

The National Fire Protection Association (NFPA) recommends defining three boundaries to minimize risk of electrical injuries. Part of NFPA 70E highlights what each boundary is and how to determine where to place it. It breaks down to basically be, as you move closer to the exposed and live equipment, the more training and higher levels of personal protective equipment (PPE) you need.

- Arc flash boundary

The arc flash boundary, or restricted approach boundary, changes depending on the potential arc flash hazard. The arc flash boundary is calculated to 1.2 calories/cm2 of incident energy. That’s the distance where a worker without appropriate PPE would receive second-degree burns.

Sometimes this boundary is the furthest one from the exposed equipment, other times the limited approach boundary is the furthest out. When the arc flash boundary is the furthest away, it becomes the line no one should pass without training and PPE. If the limited approach boundary is further out, then that should be treated as the line no one should pass without training and PPE. - Limited approach boundary

Moving toward the energized and exposed equipment, you’ll find the limited approach boundary. Within this boundary, it is still possible to be exposed to a shock hazard. Appropriate PPE should be worn by qualified workers in the limited space (space between the limited approach boundary and the restricted boundary).

Non-qualified workers should stay outside of this boundary unless wearing proper PPE and being escorted by a worker with specialized training. - Restricted boundary

The area closest to the live, exposed equipment is within the restricted boundary. In order to pass this boundary, you must be a qualified worker with the proper training and PPE. If you need to perform work on the energized equipment, you may also need a work permit and documentation.

Equipment considerations

Work on de-energized equipment: It’s the only way to eliminate hazards. Follow the lockout/tagout procedures and, whenever possible, take measurements while the system is de-energized. Be sure to test for absence of voltage before conducting any tests without the necessary PPE. Until absence of voltage testing proves the circuits are dead, they must be considered energized.

Inspect equipment regularly: You can catch some wear and tear before it becomes a problem by regularly inspecting your equipment. Knowing the history of your equipment and what a normal reading looks like can help you identify abnormalities. Gather baseline readings by inspecting critical components like electrical connections, insulation and circuit breakers.

Checking the equipment regularly using condition monitoring tools or IR windows can also help you catch an issue before it’s too far down the road. Knowing the machine’s health history means you can take any necessary corrective actions at the right time.

The right tools for the job

Safety ratings: Test instruments must go through standardized testing in order to meet safety requirements. The CAT and voltage ratings listed on the test instrument and any accessories also need to match or exceed the electrical environment where you will use them.

Look for tools that meet IEC standards with an independent lab testing verifying it. The lab’s symbol on the tool means an independent testing agency has checked the safety claims and CAT ratings and the test instrument passed.

Test tool condition: Be sure you’re not using tools or accessories that are outdated or defective. While your digital multimeter should last for a long time, it can still break or wear down eventually. Accessories and smaller test instruments should be replaced more regularly. Test leads, temperature probes and fuses, for example, won’t work accurately forever.

Inspect any test instruments before you use them. Look for any extra wear and tear, cracks, fraying or insulation showing. Make sure any connections are secure. And, use the live-dead-live testing method to ensure your instruments are working properly before and after taking a measurement. The live-dead-live testing method requires testing the functionality of your equipment on a known voltage source before and after taking a measurement.

Stay out of the arc flash boundary: There’s no need to put yourself in an arc blast zone if you don’t need to be. Products like remote display, wireless and non-contact tools can help put you further away from danger or let you take readings on an energized part without making contact.

- Non-contact voltage detectors or electrical testers

- Non-contanct infrared thermometers

- Infrared cameras

- Remote display multimeters

Arc flash vs arc blast

Following these safety guidelines will help you stay safe in the event of an arc fault, but it’s important to also understand the how and what. How is an arc fault caused and what is the difference between arc flash and arc blast? Read arc flash vs arc blast for more information.