Based on you, built by Fluke - that's a phrase you've probably seen in our ads, but what do we really mean by that? Our innovation is sparked by real life - your life on the job. In the process of developing new products we spend a lot of time with customers watching and listening. We need to understand the challenges you face in getting your job done, and we respect and seek out your expertise on the types of tools you need. Your input is an integral part of our engineering and design process, as we apply new technology, develop product concepts, and build prototypes until we come up with the winning combination of form and functionality.

So we'd like to take you on a virtual tour of Fluke to experience some of what happens behind the scenes and give you some insight into how new products are born.

It's the Fluke culture

You notice the Fluke culture from the moment you walk in the front door. On the wall of the Fluke lobby, the motto of our founder, John M. Fluke, Senior, is a visible reminder of his vision: "We must always recognize the customer is our boss. We exist to serve their needs and they have the right to get a little more than they thought they paid for." A re-creation of his modest office and the first calibrator he designed are on display. Murals of customers using Fluke products from the early days through to our latest innovations attest to our long legacy of leadership.

Before you walk upstairs, you can take a moment to peer through the windows into the model shop, where prototypes of products under development are molded and machined within days of concept. If you continued down the corridor you would see the door to the safety lab. Fluke products are put through rigorous testing to ensure they comply with industry safety standards and will perform accurately and reliably. Those are hallmarks of a Fluke product around which there is no compromise. We blow up a lot of tools to make sure the one in a customer's hand performs and protects.

George Allen, director of product planning, explains: "Customers hire our tools to do a job. A tool is judged by the job outcome. How well did it accomplish the job for which it was intended? Simply put, a good product does a good job."

George and his team of product planners spend a lot of time in the field with customers. "We try to understand exactly what the customer is doing and what his or her needs are. By carefully listening and observing, we make tools that are the best fit for that job."

"If we left the competitor's product and a Fluke product in the customer's hand, we'd want to come back in two years, and find the Fluke tool still in the person's hands because it empowers the user to do a better job."

Fluke 233 Remote Display Multimeter - both with remote displays.

Stephanie recalls the quest for wireless technology. "Sometimes it takes a long time to get the right solution. We started working on wireless in 1995, trying to solve the engineering problem of separating the display from the main measurement device so customers could see the display while at a distance from their meter."

"Over the years we tried a wide range of solutions, from very large glasses with heads-up displays to a Dick Tracy-style communicator, and funny-looking little devices that could be clipped onto a hard hat or baseball cap. While we could achieve the wireless communication, we never overcame the 'dork factor' with these attempts."

Watch video to see early experimental models for wireless

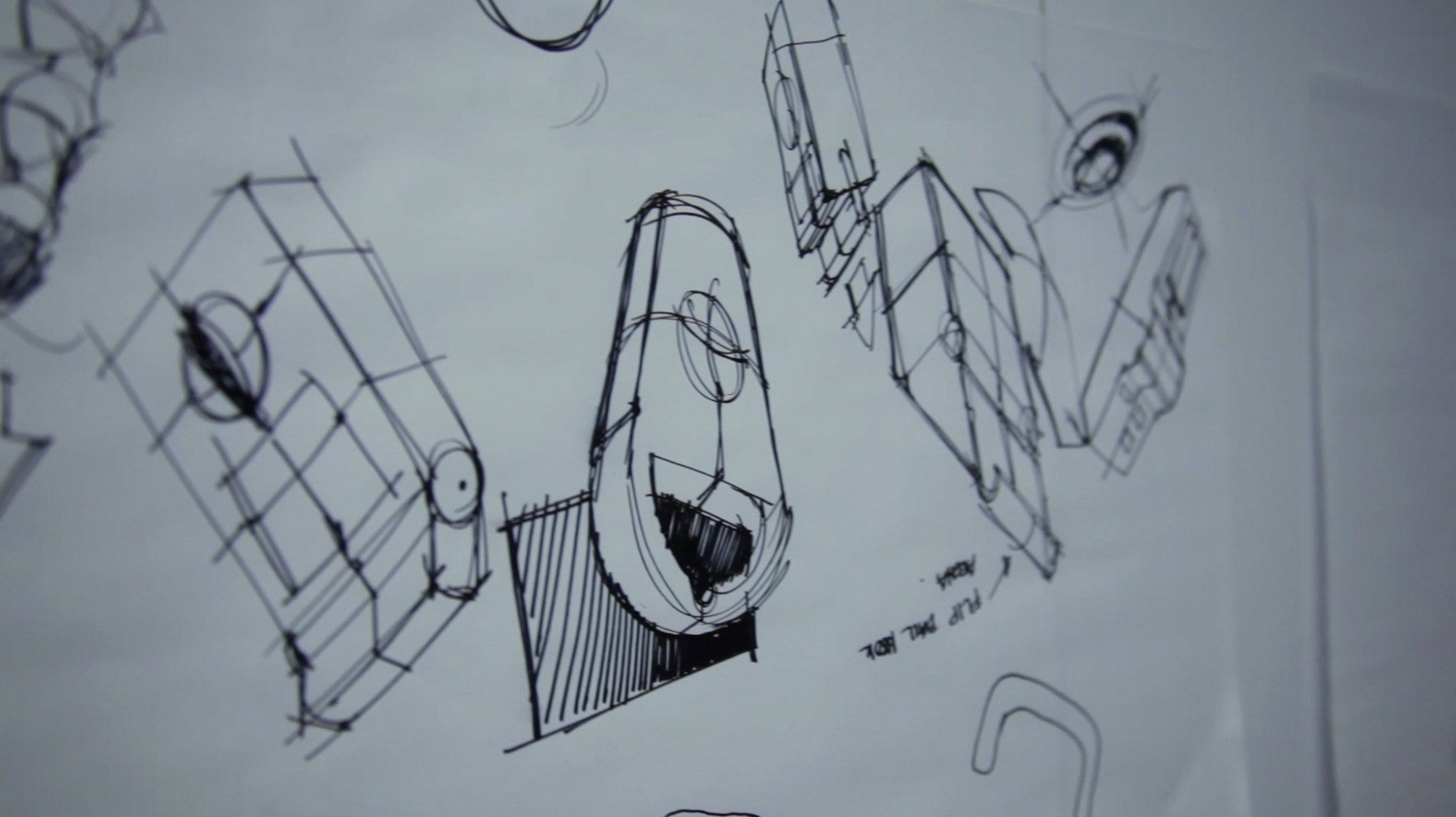

Industrial design

Let's move on to our industrial design area, where they spend a lot of time with customers. This team knows that the form factor of Fluke products is very important to achieving a satisfying experience for customers.

Matthew Marzynski, industrial design manager at Fluke, talks to us about the importance of ergonomics in product design.

"We approach the design of a product from three levels: proportion, surface, and detailing. We look at the way a customer holds the device - its mass, the silhouette, how it feels in the hand."

The way customers interact with a device is also very important to take into account. Matthew explains: "While we have to design it around the hand we also have to make it viewable and transportable. We tend to prototype a lot."

As a product progresses from an initial concept through the development process, the designers create models with various materials. Beginning with foam, then using CAD models and a 3D printer, they can quickly create accurate prototypes from a plastic resin.

As we saw in the model shop at the beginning of the tour, Fluke has its own machining equipment that can be programmed with just about any geometry to mill parts from just about any material. "With these prototypes, we can go back out to customers very quickly - within days - and actually hand them a part. It helps our customers to take an active role in designing the product."

"Now we can ask them: How does it feel in the hand? How well does it work while wearing gloves? Can you read the display when you're wearing full personal protective equipment (PPE)? In the process we learn how it performs and how they think they are going to use it."

Watch a video as Matthew shows you some of the stages of product development

More about innovation at Fluke

We hope you enjoyed meeting a few of the people at Fluke who are dedicated to developing and engineering the most rugged, reliable and innovative test tools in the world. To learn more about innovation at Fluke, read: 60 Years of Fluke Innovation. We'll be posting more interviews and commentary in the weeks ahead. There is a place on the site for you to give us your ideas and inspirations for new innovations too. Like we said, Based on you. Built by Fluke.