The Industrial Internet of Things (IIOT)-the concept of interconnected applications, equipment, and technology- is more than just an abstraction. The IIOT is the idea that connections between the digital (e.g., mobile devices and computers) and physical worlds (e.g., plant equipment and test equipment) improves information exchange.

The practical applications of IIOT to plant operations may not seem clear at first, but when compared to more traditional methods of tackling operational challenges at the plant, the advantages become evident.

One way to understand the key differences is to compare two approaches to three-phase motor failure -- smart technology versus traditional analysis.

The problem: Three-phase motor failure

As often happens, a plant faces a problem motor, one that has been replaced twice in the past six months. Finding the root cause of motor failure is the task at hand. After finding that the insulation in the windings is breaking down, the technicians at the service shop think the motor might be running hot. They are not sure if is being caused by electrical power quality problems, mechanical wear or environmental or operational stresses that degrade the motor performance. It's therefore determined that a team is needed to collect current, voltage, power quality and temperature measurements in order to isolate the fault and identify the root cause.

The solution: Traditional approach

- Individual measurements:Using standard tools (digital multimeter and clamp meter), technicians begin researching the problem: measuring voltage and current, one phase at a time.

- Logging:If the first round of measurements uncovers no discrepancy between phases, the problem may not have manifested yet. They may turn to logging of phases either with a power quality logger, clamps or logging multimeters.

- Temperature readings:Over a week, techs will use their infrared temperature gun to get a surface temperature from test points on the motor and a thermometer to gauge ambient temperatures.

- Scattered or incomplete data:It's going to happen again. Even with a computerized maintenance management system (CMMS) in place, it's tough to isolate variables and correlate among current, voltage and temperature all while the operational conditions are changing. It's a time-consuming task in order to assemble a holistic view of failure patterns for all of the plant's assets.

- Overcompensation:Failing to isolate the variables or correlate current, voltage and temperature data, the maintenance team may conclude the motor is undersized and make an unnecessary replacement of an oversized motor. Yet that will still not solve the underlying problem

The solution: Using Smart technology that communicates between plants, equipment, and employees.

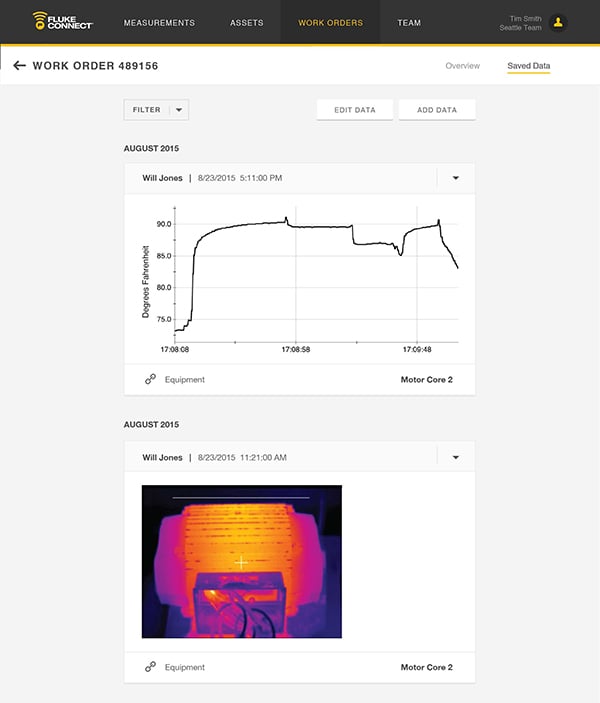

- Individual measurements:Using wireless tools that are networked to data systems and each other, across employees and work sites, can create a trend of volt and current measurements over time.

- Discrepancies between phases are quickly identified as occurring at certain times of day, therefore ongoing logging is deemed unnecessary.

- Temperature readings:Data on temperatures have been logged and stored and are easily pulled down by the techs so they have a baseline with which to compare infrared temperature measurements of the motor, relevant to ambient conditions and potential operational stresses.

- Holistic picture of three-phase motor failure: Even with a computerized maintenance management system (CMMS) in place, isolating key variables and correlating with voltage, current, and temperature is easier with a networked series of tools, all with access to trend data.

- Addressing problems with the right solution:Unlike traditional methods that might fail to identify the root cause, having real-time access to data, communication between team members and plant equipment, the IIOT philosophy of management reaches conclusions faster. As a result, a plant can operate more efficiently, potentially preventing complete equipment failure, and unnecessary equipment replacement.

While the concept of Industrial Internet of Things might seem an overly vague abstraction that applies only to Silicon Valley types, the practical application of networked tools with real-time access to data and enabled virtual communication between equipment, laptop, phone, and other technology, makes clear this isn't the case.

As the example above demonstrates, building a solid maintenance program with the right smart tools anticipates and addresses equipment failures before disastrous shut downs and unplanned equipment failure. As such, greater efficiencies and pinpointed root cause allows for a faster, simpler management of plant equipment and operations.