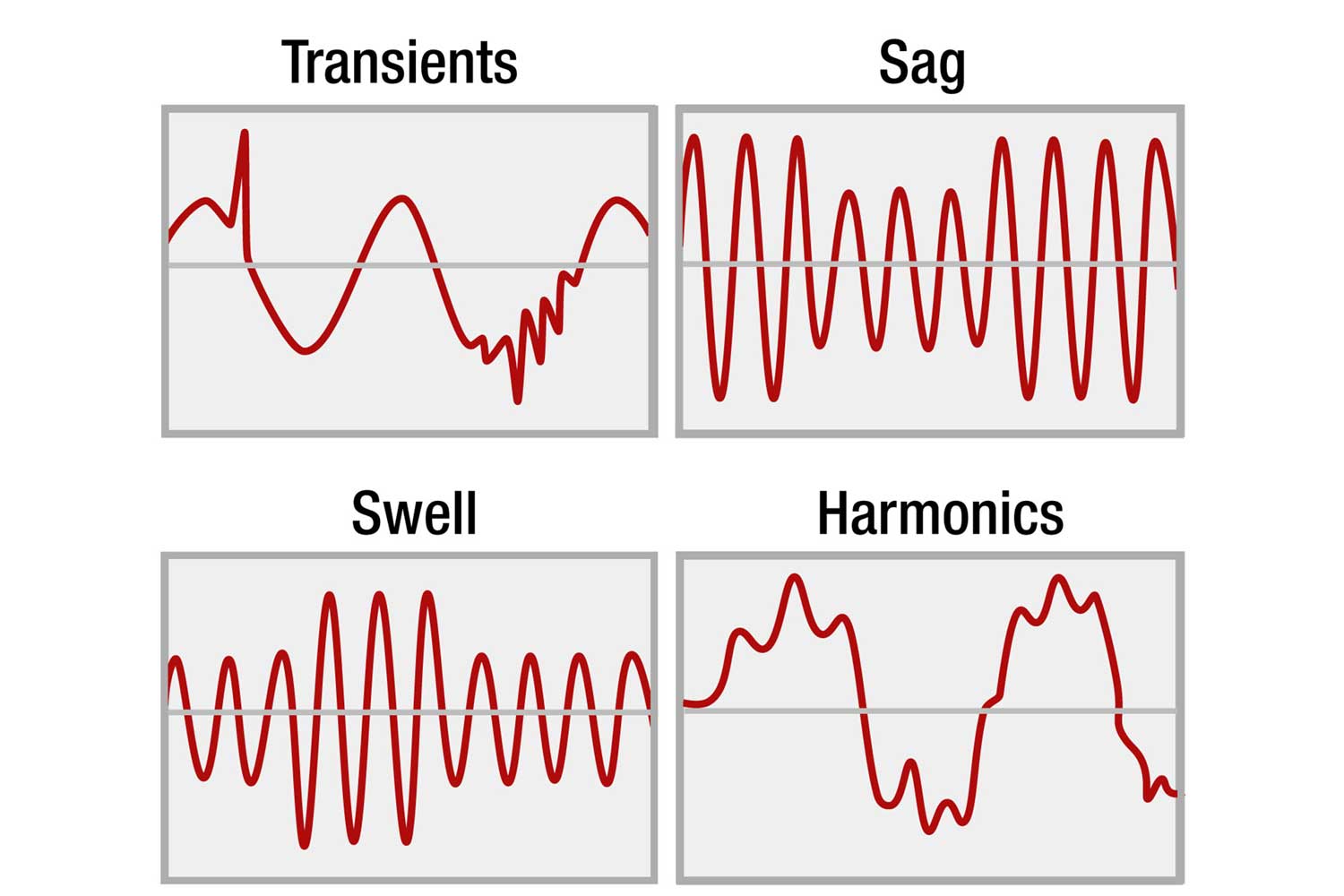

To the untrained eye, problems in electrical distribution systems or the equipment connected to the circuit may not be recognizable as power quality problems. When no immediate problem is apparent, it may be written off as just an old breaker that needs replacing or a one-time nuisance reset. You might look at types of loads on the system and monitor for harmonics, unbalance, or disturbance patterns.

Harmonic distortion issues and voltage and current anomalies represent the areas where common problems in power quality occur. Voltage and current anomalies can produce problems; however, many can be corrected before they damage equipment. Spot the symptoms:

| Issue | Symptoms | Potential causes |

| Dips or Sags | Lighting dimming, computer lockups, relay and contactor chatter or complete dropout, equipment and system shutdowns Spurious and unexplained alarms and shutdowns | Starting large loads, especially large inductive Similar operations in neighboring facilities Severe weather |

| Swells | Failed power supply Overvoltage shutdowns and alarms on variable frequency drives (VFDs) | Fault on single phase of three-phase system Sudden load decrease Capacitor bank switching |

| Transients | Flashover and arcing effects in distribution equipment Damaged insulation Failed electronics Computer lockups | Lightning strikes Switching of capacitors Reenergizing systems after a power failure Sudden stoppage of large equipment Dirty or worn contactors |

| Interruptions | Equipment shutdowns | Momentary loss of utility power |

| Unbalance | Overheated three-phase motors and transformers | Unbalanced loads across individual phases of three-phase panelboards Unbalanced utility supply Operation of single-phase welders Open-delta transformers |

| Harmonics | Open-delta transformers Overheated transformers Overheated inductive motors Spurious and unexplained alarms and shutdowns of electronic equipment | Nonlinear loads such as switching power supplies Converter sections of uninterruptible power supply (UPS), VFDs and battery chargers Welders Arc furnaces |

Power quality analyzers and loggers

A Power Quality Analyzer can help to recognize these common power quality problems. You’ll never miss a critical power quality event with a power quality analyzer. Whether you’re performing a quick system check or a detailed power quality study, consistent data is key. Plugging the 1770 series into your assets, the tool offers a unique automatic measurement capture system that helps ensure you’re collecting the right data every time—from fast transients up to 8 kV, harmonics up to 30 kHz, dips and swells, as well as the voltage, current, and power measurements that enable you to characterize problems in your electrical system.

Power Quality Loggers make it easy to profile energy usage in your facility. They deliver power-measurement data so you can discover and mitigate sources of electrical energy waste or overloaded circuits. These tools are great to have in-hand for routine load studies and preventive maintenance programs.

- Fluke 1732 and 1734 Three Phase Power Measurement Logger

- Fluke 1736 and 1738 Three-Phase Power Quality Loggers

- Fluke 1742, 1746 and 1748 Three-Phase Power Quality Loggers

Power Quality Recorders are the tool to grab for advanced power quality analysis. Uncover the root cause of equipment malfunctions with load studies and transient analysis so you can later go back and make necessary repairs or develop baseline information for routine load studies.

- Fluke 1760TR Three-Phase Power Quality Recorder

- Fluke 1760 Basic Three-Phase Power Quality Recorder

- Fluke 1760TR Basic Three-Phase Power Quality Recorder

- Fluke VR1710 Single Phase Power Quality Recorder & Voltage Recorder

Electrical measurement windows

Electrical Measurement Windows are an additional tool to make measurements with these tools easier. An electrical measurement window is permanently installed into the face of a cabinet with the necessary connections ready to go. Instead of having to open the cabinet, you can just take measurements at the window, making it a safer process for routine preventive maintenance or load studies.