Download PDF: Is it the motor, the drive, or the load? »

Where do you start when troubleshooting problems?

In troubleshooting situations involving a motor, more than half the battle is simply isolating the problem. Whenever there's a working motor, there's a load and there's some sort of motor controller, which is increasingly going to be an adjustable speed drive (ASD). So when problems arise, how can you tell if it is the drive, the motor, or the load? Here are a few tips to tackle the problem in a quick, systematic way, making a few key measurements as you go.

Imbalance measurements

A good place to start is with a measurement of current drawn by the motor. When we talk about motors here, we are referring to three-phase induction motors, the workhorse of industry. Motors are balanced loads: the current that they draw on each phase should be about the same (less than ten percent, as measured below). If they are not balanced, he cause could be internal to the motor (deteriorating stator insulation, for example), or it could be the result of voltage imbalance. So if there is any problem with current imbalance, make the voltage imbalance measurement (less than three percent) at the output of the ASD. The following calculation works for either voltage or current imbalance.

ASD overvoltage and undervoltage trips

Drives have diagnostic codes which identify the cause of trip. Generally speaking, they can be classified as overvoltage, undervoltage, or overload (overcurrent). Note that mechanical starters only have overload trips. They're not concerned with over or undervoltage. What makes drives different?

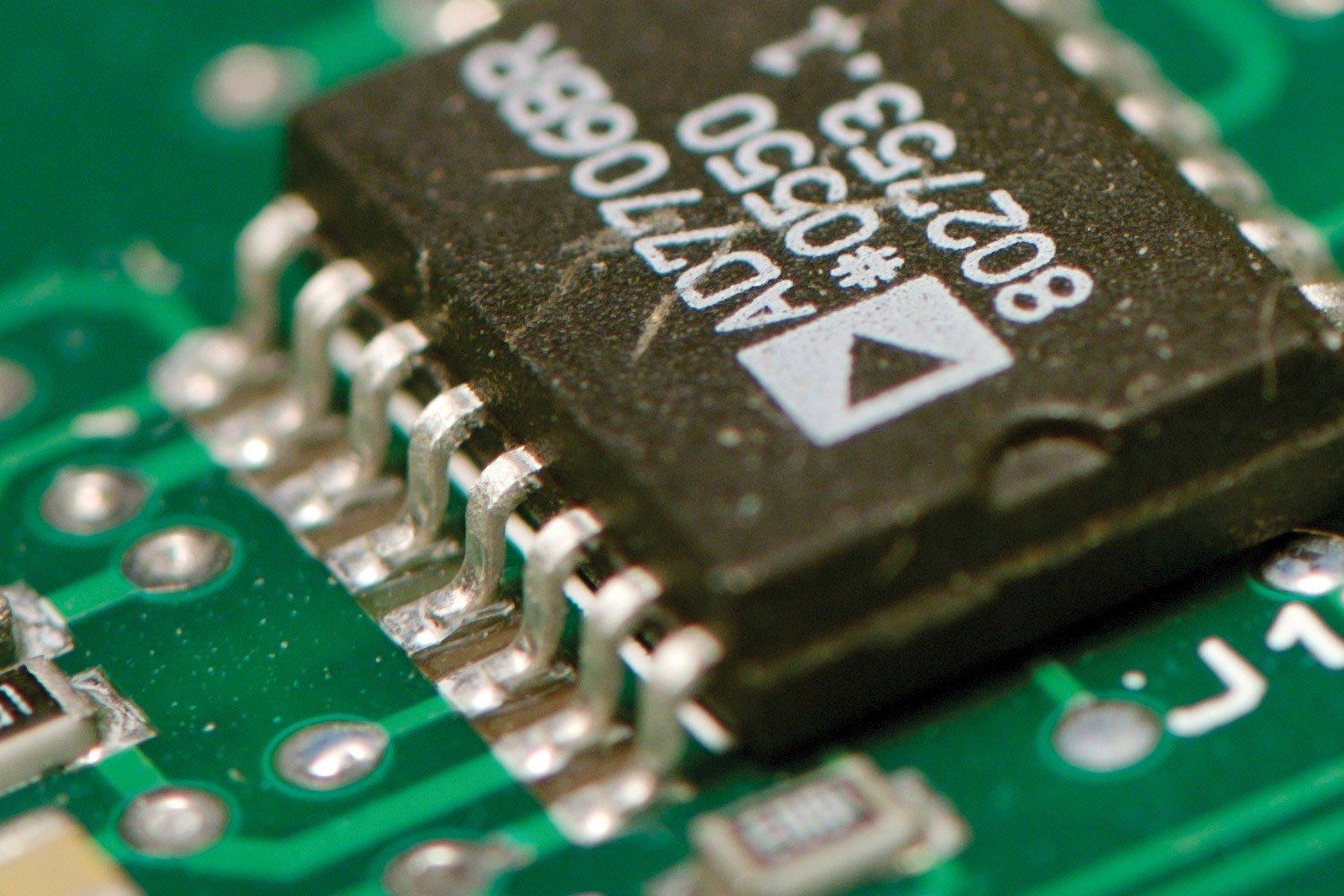

Drives turn sine wave ac into dc (converter section), and then turn the dc back into ac (inverter section). However, the ac at the output is not a sine wave. It is a special waveform known as the pulse-width modulated (PWM). The PWM, from the motor's point of view, is accepted as if it were a sine wave - almost (see Advanced motor measurements below). For now, though, let's focus on the drive internals, specifically on what's commonly referred to as the dc link. The dc link is nothing but a capacitor bank, usually with a series link inductor (reactor) thrown in for filtering and protection. The dc link is carefully monitored by the drive; overvoltage or undervoltage refers to the voltage of the dc link.

Undervoltage can be caused externally by voltage sags on the drive input. The Sags and Swells function on Fluke power quality analyzers can help to identify line-related undervoltage problems. Problems could also exist internally with the dc link capacitors and/or reactor. In many drives, there are test points to measure the dc link voltage. To check the capacitors, use the min/max function of a digital multimeter, or, preferably, the trend function of a Fluke power quality analyzer or ScopeMeter® test tool. Check if voltage regulation is within the manufacturer's specification. To check the reactor, check the waveform on both sides - there should be no change.

When troubleshooting a system, the tendency is to view the drive or PLC as the most susceptible to voltage sags. The ice-cube control relay is most often the source of sag-related problems. Studies have shown that these low-cost components are the first to drop out when voltage sags occur. So don't forget to look at any external control circuit while you're troubleshooting intermittent system shutdowns.

Load profiling

To troubleshoot the interaction between the load and the motor, you have to understand the relationship between torque and current. A motor is nothing but a device to turn electrical energy (current) into rotational mechanical energy (torque), via the magical effects of magnetism. What a load demands of a motor is torque. For all practical purposes, this torque is directly proportional to current used by the motor. This should make perfect sense, because we all know that for constant-speed motors - which include all motors started across the line (with electro-mechanic starters) - voltage is, or should be, stable, and current is the variable. When a load demands more torque and current than a motor can supply, the result is an overload condition. Overloading will cause overheating of the motor. Motor controllers will shut down the motor (and thereby the load) rather than allow permanent winding insulation damage to occur. verloading is always relative to time: a high overload will trip the motor in a short time, while a lower level of overload will take longer to trip the motor.

Two different loads:variable torque and constant torque

Most drive systems are used with variable torque or constant torque loads. Variable torque loads include fans and rotary pumps. These are by far the majority of loads, from an energy consumption point of view. When ASDs are used with these loads, dramatic energy savings can be realized. From a troubleshooting point of view, the important thing to realize is that these variable torque loads rarely cause overload-related problems for drives (assuming the load has been sized correctly).

Constant torque loads can be more challenging. Frictional or gravitational loads are constant torque loads. The key thing to understand about these loads is that they require the same level of current (more or less) at lower speeds. This can be dangerous for the motor. Motors are usually cooled by fans built onto the rotor; when the motor slows, the fan cools less. Therefore excessive heating can occur. The danger is that motor overload circuits are built to measure heat indirectly by measuring current (there are motors with heat sensors embedded in their stators, but these are obviously more expensive).

Advanced motor measurements

In ASD motor systems, there are a few measurements that need to be taken that would not be taken in mechanical starter (across the line) motor systems. This is because the fast switching, high-frequency element of the PWM output waveform causes special problems that the sine wave doesn't. At first glance, the motor as a current-drawing load looks like nothing but a big set of inductors or coils (stator windings), and the nature of inductors is that they filter out the high frequency current elements. That is why the current waveform looks like a sine wave. But unfortunately, those high-frequency elements of the voltage waveform do not get filtered out, and are capable of causing some mischief.

The first two of these measurements should be made with a ScopeMeter or with the Scope function of a Fluke power quality analyzer:

- Overvoltage reflections.

- Motor shaft voltages and bearing currents

- Leakage current.

What about harmonics at the output of the drive? Wouldn't the PWM-turned-into-sinewave current-waveform contain a lot of harmonics? Absolutely. But we don't have to measure these. First of all, they don't get into the rest of the power distribution system; they only affect the motor. Specifically, they cause additional heating in the motor. However, motor and drive manufacturers have addressed this problem by supplying higher grades of motor insulation. In those cases where an older motor is retrofit with an ASD, the recommendation is that the motor full load amp be derated.

Click here to download the full pdf: Is it the motor, the drive, or the load? »