Motors and drives, the key components of any facility, are used everywhere and can be prone to a number of unseen problems. It's important to manage preventive maintenance on your motors and drives and to use the right tools to help you diagnose the areas that are most prone to failure.

With motors becoming increasingly more complex and technical, keeping them running at peak performance continues to be a growing concern. Equipment failure can result in high monetary losses both from potential motor or parts replacement, energy spikes, and equipment downtime causing production stops.

This application note offers four key strategies for success, and explores:

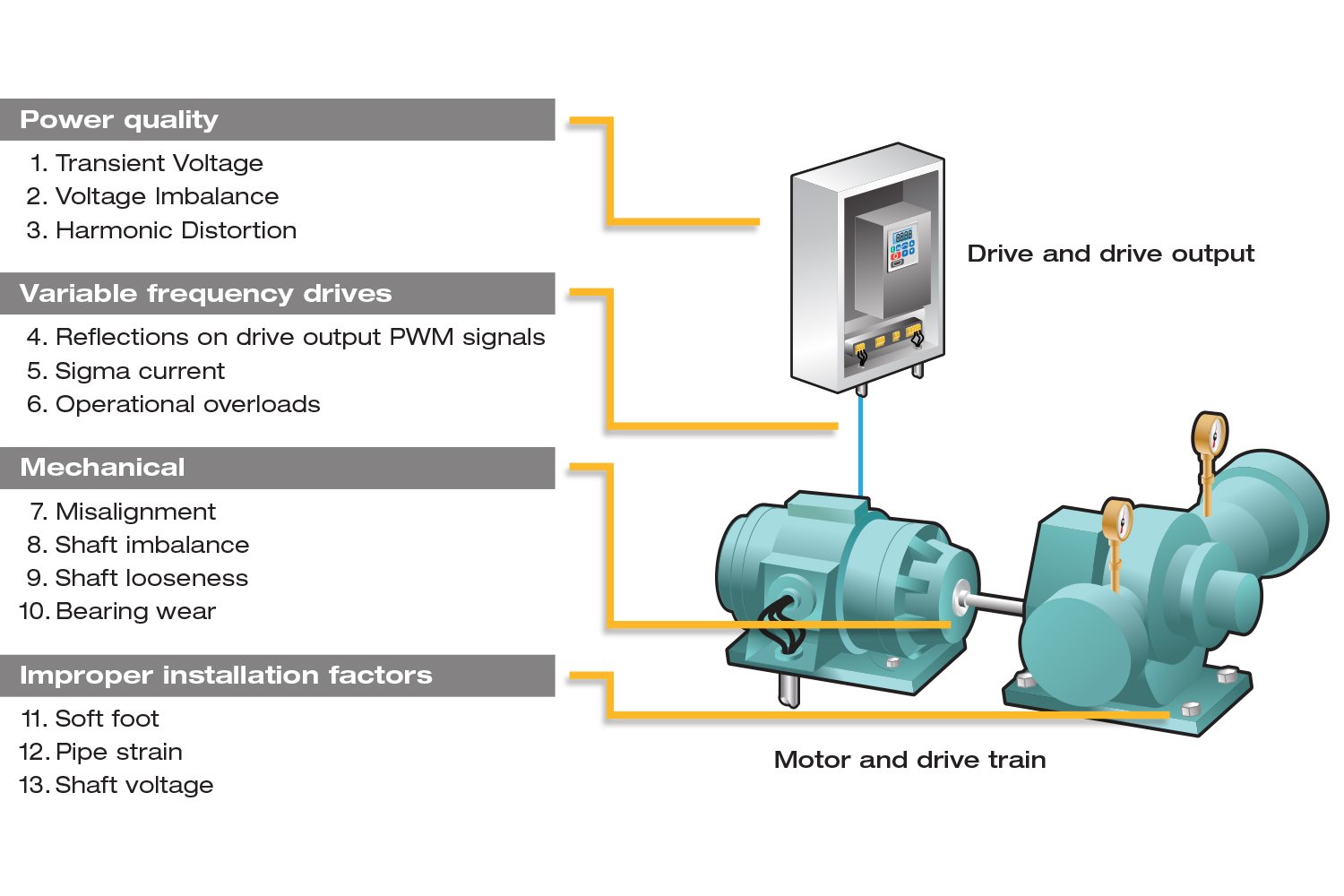

- Common causes of motor failure

- What to look for

- What the impact is

- What tools to use

- How critical the issues are

Trust Fluke to help you move away from reactive maintenance, give you the right knowledge, and manage preventive maintenance to avoid failures.