By Ron Auvil

One of the possible problems in facilities today is the presence and effects of mold on the indoor environment. Molds are normally present in nature. They reproduce by means of tiny spores that float through the air and are invisible to the naked eye. They can grow on wood, paper, carpet, foods, and insulation - but none of the many types of mold will grow without water or moisture. When excessive moisture accumulates in buildings or on building materials, mold growth will often occur, particularly if the moisture problem remains unaddressed.

It's impossible to eliminate all mold and mold spores in the indoor environment. However, mold growth can be controlled indoors by controlling moisture indoors. If not found and remediated, mold will cause significant indoor air quality issues leading to possible illness, productivity loss, and litigation.

Some moisture problems in buildings have been linked to changes in construction practices during the 1970s, 80s, and 90s. Some of these changes resulted in tightly sealed buildings that may lack adequate ventilation, potentially leading to moisture buildup. Building materials such as drywall may not allow moisture to escape easily. Other moisture problems may include roof leaks, landscaping, gutters that direct water into or under the building, and unvented combustion appliances. Delayed or insufficient maintenance is also associated with moisture problems in schools and large buildings.

Job Scenario:

A large university in the Southeast USA is facing complaints from students living in several dorms. Complaints include hay fever-type symptoms such as sneezing, runny nose, and red eyes. Some students have also displayed a skin rash. Also, several students with known mold allergies have experienced asthma attacks. Complaints from parents have increased. The campus health professionals have been consulted along with the local health department.

Step #1:

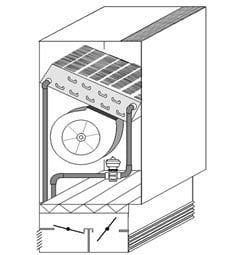

An inspection team thoroughly examines a number of rooms and their associated HVAC systems, following EPA guidelines. The different buildings on campus utilize different HVAC systems. The university is in a hot climate with a very high average daily humidity. The complaints and symptoms are taking place during very hot weather. Some of the buildings affected use fan coil units with chilled water coils and others use air handling units with air distribution.

Room #1:

The first room checked uses a chilled water fan coil system. The measured humidity underneath the sink is 63% RH. This is above the upper limit value of 60 % RH set by the EPA to reduce mold growth. Other readings at various spots in the dorm room vary from 45% to 61% RH. A visual inspection underneath the sink reveals the presence of mold.

The team also uses the Fluke 975 AirMeter to check the accuracy of the room temperature sensor, which is connected to the building automation system (BAS). The sensor is found to be accurate within .3 °F, which is within the listed tolerances for the sensor.

The room is very warm, approximately 78 °F. A check of the fan coil system discharge air temperature reveals a temperature of 65 °F. The BAS is checked and the chilled water valve is listed as 100 % open. A visual check of the valve confirms this.

Based on previous experience, the team knows that the discharge air temperature should be approximately 55 °F with the valve wide open. They suspect a problem with the coil, valve, or water distribution system. One tech uses a Fluke 179 Digital Multimeter with a 80PK-8 contact thermometer connected to the chilled water inlet pipe to the fan coil unit. The water temperature reads 49 °F. Standard ARI chilled water supply temperatures for centrifugal systems are 44 °F. At this point, the team checks the return temperature, as well. It's 59 °F.

The university has a separate department responsible for the chilled water distribution system. When asked about the measured temperature of 49 °F, they say that the chilled water temperature has been raised in order to save energy at the central chiller plant. Based on these temperatures, the chilled water coil cannot provide the proper dehumidification.

After high-level discussions with the university chilled water plant management, the supply temperature set-point is reduced. The coil discharge temperature drops and the team measures verifies the new temperature with the AirMeter. The room humidity immediately begins to drop as well. The mold growth is stopped and the existing mold is remediated.

Room #2:

Another room on the chilled water fan coil system, in the same building as the previous fan coil unit. The chilled water supply temperature problem has been corrected, but mold problems persist in this room. The team checks the room's temperature sensor and confirms that it's functioning correctly. As in the previous example, the room is very warm, approximately 78 °F. The fan coil valve is wide open and discharge temperature is 55 °F.

While visually inspecting the unit, the team determines that routine preventive maintenance has not been performed in some time. The fan coil unit is a large model with a belt driven fan. The belts appear loose. A The team uses a Fluke 902 Clamp Meter on the motor leads. The motor full load amperage is 5 amps but the meter only reads 3.5 A. The team replaces the belts immediately and measures the motor amps again. It now reads 4.9 A.

At the same time, they notice that the filter element appears dirty. They use the Fluke 179 Digital Multimeter with a PV350 pressure module to check the pressure drop across the filter. It's 2 inches w.c. (inches in water cooler). The listed pressure drop from the filter manufacturer is 1 in. w.c. The team replaces the filters and puts the unit back into service. The next day they repeat their measurements and the humidities are all under 50% RH.