By Chuck Newcombe

I'm sure that by now you've all seen that little twisty compact fluorescent lamp (CFL) in the store when shopping for replacement lightbulbs. The good news is that when you use one for replacement of a trusty incandescent bulb, you'll be saving energy. One example at our house: a five-lamp chandelier that consumed 300 watts now uses just 60 watts, the equivalent of one incandescent bulb, while producing the same amount of light as five. These CFLs, and the newer and much more expensive light-emitting diode (LED) units, are being introduced to replace the less efficient tungsten bulbs that are being phased out by 2014 in the United States.

CFLs cost more, but an offsetting feature is that they last longer. The caveat: that only happens if you don't turn them on and off a lot, and you don't use them outdoors in cold climates. It turns out the little heater that helps ionize the vapor in a CFL at startup still has the same characteristic as a tungsten incandescent lamp - its resistance is very low when cold, but becomes much higher as it warms up. That's why your incandescent lamps usually burn out at turn-on - you are stressing the tungsten filament with the highest current flow at turn-on.

One approach to getting full life out of a CFL bulb would be to leave it on longer, reducing the heater- filament-stressing on-off cycles. In my experience, described above, you could leave it on five times as long as an incandescent lamp and not use any more energy.

Temperature coefficient of resistance for tungsten

The typical cold resistance of a 100 W incandescent lamp is about 9.5 ohms. If that resistance stayed the same with 120 V applied, Ohm's Law tells us that the bulb would draw about 12.5 amps and dissipate about 1,500 watts. That doesn't happen of course, and that's because as the filament heats up, its resistance increases as well. It turns out that at 120 V, the resistance is about 144 ohms, 15 times the cold resistance. The resulting current is 0.83 amps, and the power dissipation is the advertised 100 W.

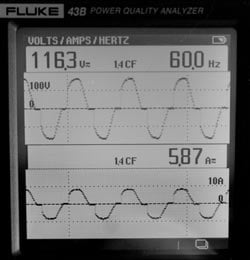

An interesting experiment using a Fluke 43B Power Quality Analyzer

It turns out that the time constant for the change in resistance as full voltage is applied can be measured in milliseconds. And, that's why the following experiment works.

When Fluke introduced its first power quality tool in 1994, I used a Triac light dimmer to vary the voltage input to an incandescent light bulb while measuring the rms voltage input and resulting current flow.

I observed that the peak current occurred at an rms voltage input of about 55 volts. In today's example, using a new high efficiency halogen lamp (more about that later), the lamp is drawing 0.39 A rms (I used a ten-turn loop through my current clamp jaws, which made the apparent reading 3.9 A.) The peak current in that example was almost 1.2 A.

As I continued to turn up the voltage, the rms current increased, but the peak current became less - about 0.8 A.

How can that happen? Well, the total time that the current is flowing in the low brightness example is less than 4 milliseconds, not enough time to warm the filament to the higher resistance that it will reach when current flows for twice that time - about 8 milliseconds. So, the peak current is higher at the lower brightness.

For this example, when you do the math (or switch to the Power display of the Fluke 43B), you will discover that the low brightness power consumed by my test lamp at peak current was about 22 W, while at full brightness the power was a little over 68 W.

More about those new halogen lamps

The lamp I used for my recent test is billed as a high efficiency halogen bulb. It is rated for the same light output as the old 100 W bulb, but uses only 72 watts. As I verified in my test, it still uses a tungsten filament. As I understand it, these high efficiency incandescent bulbs, and certain special service bulbs, will continue to be available after the old technology standard bulbs are phased out in 2014 (in the US).

How about those new LED lights?

CFLs have the environmental disadvantage that they contain mercury, requiring special handling in disposal to avoid contamination of our environment.

An emerging alternative lamp will use light emitting diodes, for even greater efficiency than the CFLs, but at a much higher cost - at least so far. LED lamps are instant-on, and don't have the cold start problems that can occur with CFLs.

The emerging technologies don't yet achieve the pleasant glow of the familiar incandescent bulbs, but they are steadily improving. If you're interested, you can review some of the issues around our changing lighting technologies here:

Phase-out of incandescent light bulbs

Energy Star information about light bulbs

How compact fluorescent lamps work and how to dim them