The best way to keep building performance high and operational costs low is to perform regular, ongoing maintenance on all building mechanical systems. Retro-commissioning is one aspect of a best-practices program to improve energy efficiency.

Not just a one-time event

The common industry definition of commissioning is to ensure that new building systems meet performance specifications.

The common industry definition of commissioning is to ensure that new building systems meet performance specifications.

Until recently, most commissioning was a one-time event, performed by a qualified commissioning authority in the building acceptance phase. What about fine-tuning needs at the same building a few years later? Or what about older buildings that were never properly commissioned? These issues are now being addressed with ongoing and retro-commissioning.

Ongoing commissioning

While most commissioning is designed to meet one-time project requirements, ongoing commissioning is designed to optimize system performance year-over-year. Ongoing commissioning happens on a regular basis. Where possible, it utilizes the features of modern Building Automation Systems (BAS). For non-BAS buildings, commissioners use standalone equipment such as temperature, humidity, and power loggers to check, and then adjust, sensors, controllers, and other system components.

Please note: The ‘adaptive’ or self-tuning control capabilities of modern building automation systems often cover up poorly operating mechanical systems. Just because it’s new and high-e doesn’t mean it’s perfect. Even the best systems need to be regularly inspected and calibrated. Otherwise, the stated efficiency performance goals will not be reached.

Retro-commissioning

Retro-commissioning applies to existing buildings and systems that were never properly commissioned when built or installed. It uses the same techniques as standard building commissioning to evaluate, baseline, and then implement changes to the mechanical equipment and other building systems. Like ongoing commissioning, it should happen routinely, with the goal of maximizing system efficiency.

The difference is that older buildings typically have fewer and/or older controls in place and more equipment challenges, requiring more footwork, measurement, analysis, and sometimes, equipment upgrades. Retro-commissioning should be performed by an experienced commissioning contractor or by maintenance personnel trained in the proper procedures.

While each mechanical system in the retro-commissioning process is different, here are some of the typical procedures.

Preventive maintenance

Before the project can even begin, perform normal preventive maintenance procedures on system equipment. Typical checks and procedures often include:

- Electrical measurement of voltage, current, phase and temperature of electrical equipment. Compare the readings to those previously recorded and determine changes in equipment sequence and operation.

- Filter changes, pressure drop measurements of filter banks.

- Check RPM of motor driven equipment of pumps and fans. An RPM change may indicate a drive problem that is causing the device to slip.

Calibrate critical sensors

One of the major contributors to high energy consumption in commercial buildings is sensors that are out of calibration.

These sensors are usually wired to modern building automation controls and are used to perform closed loop control, monitoring, and alarming. If these sensors are out of calibration by even a few units, the system will consume excessive energy. Also, out of calibration sensors will feed faulty information to building automation functions such as alarming and data trending (logging). These problems are especially pronounced for important building areas such as operating rooms in hospitals, labs, and high-quality production sections.

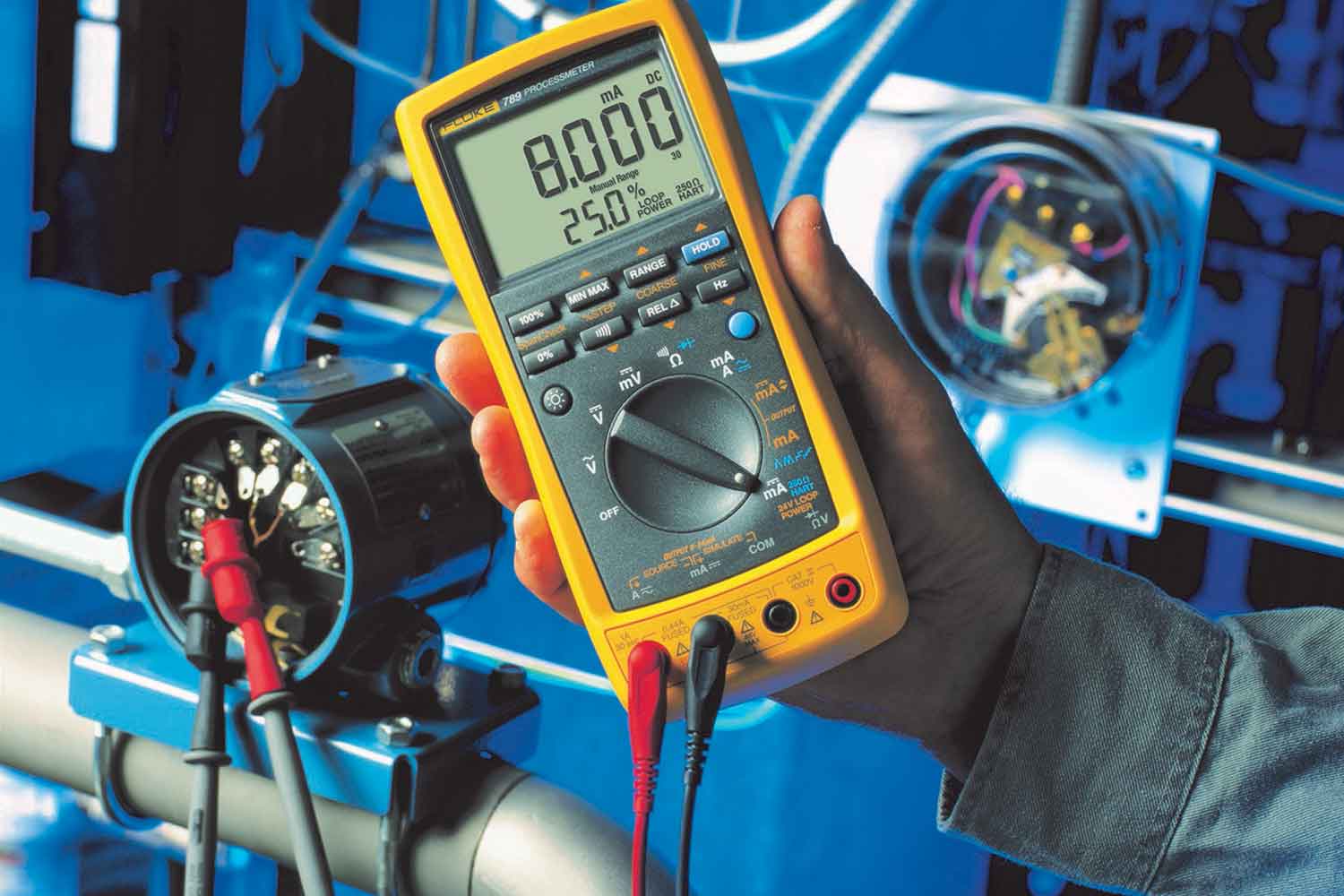

While there are many types of sensors, by far the most common are temperature, pressure, and humidity. Use a high-quality portable test instrument, known as a field calibrator, to measure the controlled variable while a colleague checks the sensor reading on the building automation system.

If a building automation system is not present, use a field recorder or logger to measure values such as temperature, pressure, and humidity and compare the results to standard comfort expectations such as the ASHRAE standards.

Energy consumption

Check energy consumption on a whole-building basis or for one circuit or one piece of equipment at a time. Checking the whole building is useful when evaluating utility bills, but to really evaluate equipment performance, a finer analysis is probably necessary.

While in some cases BAS instrumentation may be used, more often commissioners use portable power loggers to measure energy consumption and analyze equipment operation. For instance, say a refrigeration compressor with a known amp draw and voltage has been in operation some time. If the documentation is available, compare the energy consumption now against the previously recorded baseline amount. An increase in power consumed could be due to leaks, restricted flow, dirt, or electrical winding deterioration.

Flow rates

In addition to measuring energy consumption values, check the amount of air, water, and/or steam flow as well. For water flows, check hot water, chilled water, and others including condenser water flow from cooling towers. Again, BAS sensors may be available, but portable recording test equipment such as data loggers or field calibrators are required to check the sensor readings and baseline against previously noted values. A large change in recorded flow rates may indicate a fouled heat exchanger, piping, or pump problems. Use these results to determine a plan for repair or replacement.

Pressures

It is very important to check the air, water, and steam pressures of operating equipment and compare them to BAS equipment readings and design values obtained on equipment start up. Any variation in system pressures may indicate a mechanical system that is losing efficiency and in need of repair or replacement.

Other

In addition to the variables mentioned above, commissioners also often measure pressure drops across filters, RPM of fans and pumps, and indoor air quality values such as CO2 PPM. They compare these readings to any previous baselines and create an action plan to repair any deterioration.

In summary, both ongoing and retro-commissioning are receiving new attention as the drive to maximize facility performance continues. Either a commissioner or a specially trained technician records the values of the operating mechanical system and develops a plan to restore the system to desired performance levels and save scarce facility dollars.