Now that budgets and staff are smaller, it's not uncommon for management to ask for justification before authorizing tool purchases. The key phrase here is return on investment (ROI), or how long will it take to save enough money, using the tool, to cover the cost of purchasing the tool.

The easiest scenarios are when a tool allows you reduce the man-hours required to complete a job. For example, installing an IR Window in a panel and using a thermal imager allows one person to inspect key panel components in five minutes, versus two people spending a half hour or more and suiting up with PPE. In that instance, calculate the cost of the man-hours and multiply by inspection frequency to determine how many inspection cycles it will take to cover the cost of the window and the imager.

But what about a tool that solves a really irritating, intermittent problem that has you running all over the plant instead of doing your regular job? How do you cost that out? Or a tool that improves general productivity? Or that extends the life of equipment? Or allows component vs. unit replacement? Or helps you avoid unplanned downtime? Or allows you to complete a fix in-house instead of bringing in a contractor at night or on a weekend at $250/hour? Sometimes the hardest thing is to put a price on keeping everything running smoothly.

If you can't do a man-hour calculation, consider the equipment cost. A component vs. a unit, for example. Or, if you extend the life, then over the course of a year how much do you save by not having to purchase a new unit? And management should know the approximate cost in lost business opportunity and overhead per hour of downtime.

In most cases, common sense thinking will help you at least rough out the cost. The following scenarios demonstrate how.

Example 1: A facility with a large central cooling plant typically hires a service company to check the insulation of the cooling tower fans, chilled water pumps, and condenser water pumps. The service company charges $125/hour. This year, the team would like to do this work in-house, if possible, so they purchase an insulation resistance tester for $450. The new insulation tester is paid for in less than four hours, certainly within one cooling season. The meter then is making money every time it is used! Also, because the cooling system motors are checked at the beginning of the cooling season, the probability of costly downtime and emergency service calls are reduced. In addition, the meter is available for use with other equipment such as hot water pumps and air handler motors, increasing general productivity and reducing the payback period even further.

ROI: Tool paid for in four hours.

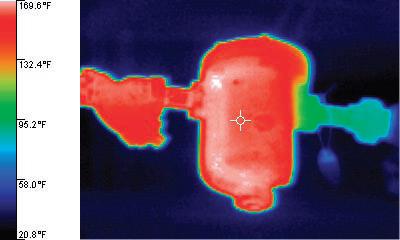

Example 2: A facility uses a large steam plant to distribute high pressure steam across the facility campus. Steam traps are used to collect the condensate and return it to the steam plant for use as feedwater. The steam traps need to be checked regularly, because if they fail open, live steam is introduced into the condensate, which wastes steam and energy. Due to staff cutbacks, the steam traps have not been checked recently and there are probably failures occurring now. According to one steam trap manufacturer's calculations, a 1" inlet steam trap at 10 psig steam, at a generating cost of $5 per 1000 lbs, will cost $4725 per year in waste. And that's just the cost of one trap. So, the team researches the ROI for buying a thermal imager to quickly check all of the steam traps on site. The model they are considering costs $4,500. In other words if one single faulty trap is found and repaired, the thermal imaging meter will be more than paid for. Every other trap after this one that is discovered will add 100% of the savings generated directly to the bottom line, season after season. And they can use the thermal imager to inspect and troubleshoot many other areas of the plant and campus and perhaps stabilize the operations and maintenance budget. Productivity per staff member will increase as well.

ROI: Tool paid for at detection of first failed steam trap.

Example 3: A facility suffers from continual refrigeration compressor burnouts, at $9,000 per compressor. These burnouts are leading to the loss of product batches that must be stored in a controlled environment, at $0.60 per unit and batches of 1500. Further, the supply irregularities are leading important customers to cancel their orders. The refrigeration compressor burnouts are also costing thousands of dollars in expensive service calls. The causes of the continual burnouts remain unknown. The team decides to purchase a power quality analyzer, for $7,500. They attach the analyzer to the incoming power of one of the compressors, and discover that the incoming power supply has major voltage and phase fluctuations that are probably causing the premature compressor burnouts. They continue testing upstream and trace the problem back to the incoming power from the electrical utility. The utility is contacted and the power problem corrected. The compressor burnouts stop. Even with the cost of this tool, the money saved from one avoided compressor burnout will pay for the analyzer. They avoid the unit price, the emergency service calls, the product loss, and the sales loss. Plus, they use the meter on other applications, improving equipment performance throughout the plant, allowing a limited staff to solve more problems and spend less time fighting fires.

ROI: Tool paid for immediately, costing less than the current waste per incidence.

Once you cost it out, all three of these examples sound like pretty good uses of limited budget dollars. The question may be not if you can afford the test instrument, but can you afford to not have it and suffer from high costs and expensive service calls?