Insulated hand tools provide two types of protection for workers around live electrical equipment. First, they help protect individuals against electrical shock and arcing. Second, they help protect the equipment being inspected or repaired. This is important because even if electricians or technicians are working on a deenergized piece of equipment they are still likely near other energized equipment. If they are using hand tools that aren’t insulated and they happen to accidentally contact an energized component it could send live voltage through the tool directly to the user.

What sets insulated tools apart?

The thing to understand is that insulated tools aren’t just regular tools with some extra rubber on the handles or generic coating on the tool end. They are designed end to end to protect workers from electrical shock up to 1000 V ac and 1500 V dc.

They provide this protection in several ways. According to the ASTM F1505 standard, the tools must be completely dielectric up to 1000 V ac. That means no part of the tool’s insulation will conduct electricity if it comes into contact with voltage up to that level.

All parts of the tool, including the insulation, must be flame resistant and must function from -20° C (-4°F) to 70°C (158°F). Tools such as pliers and cutters should have a guard rail to protect a user’s hand from slipping down to the exposed metal part of the tool.

Who needs insulated hand tools?

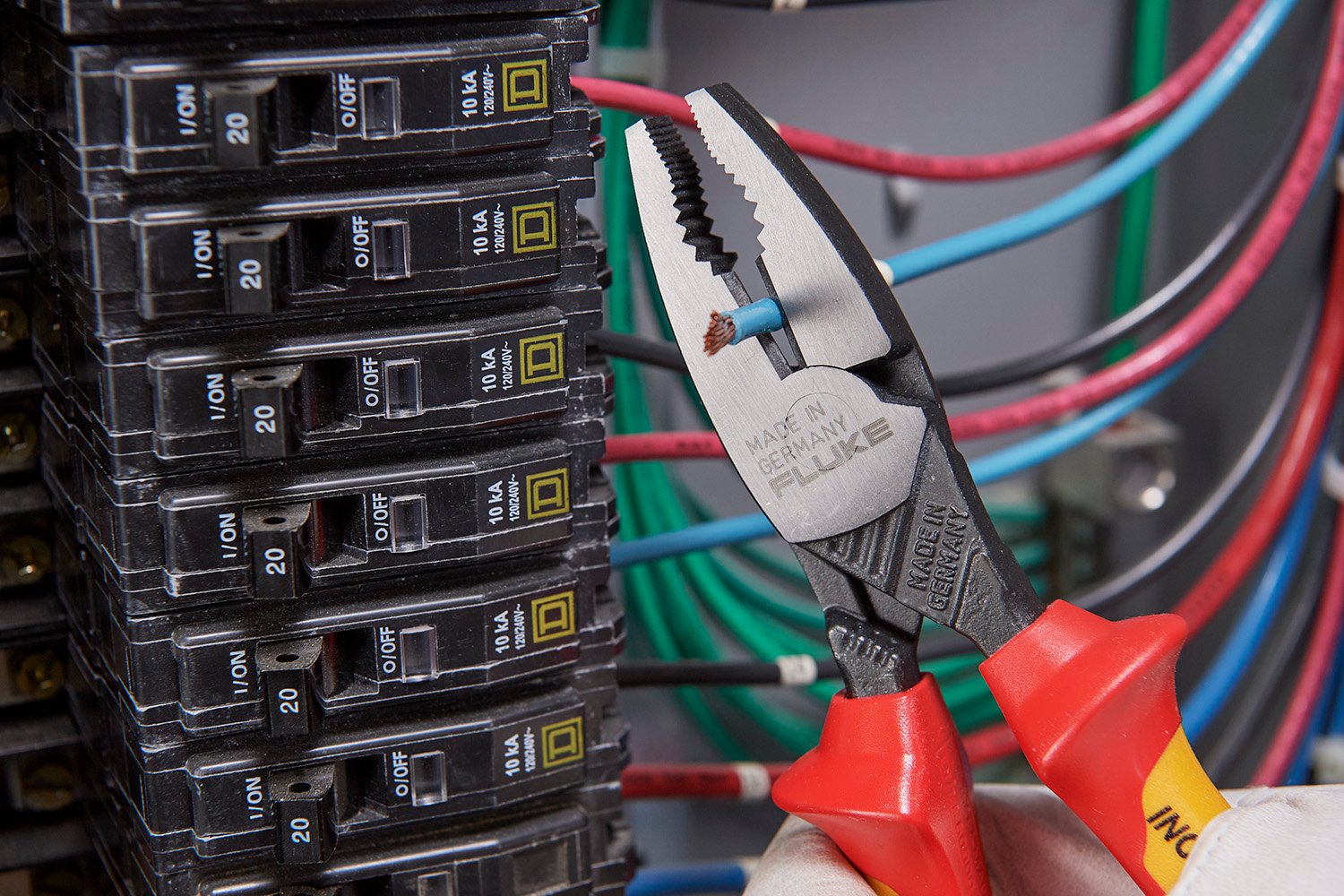

Keep in mind insulated tools aren’t restricted to electricians. They are required for anybody who works on or near live equipment. That means you need them for opening and closing panels, connecting and disconnecting electrical contacts, cutting wire, battery service, troubleshooting or installing circuit breakers in live electrical panels, and the list goes on. In selecting insulated tools be sure they are clearly labeled as such and include the voltage level of protection.

Fluke clearly labels its insulated tools as rated for 1000 V. Built of German CMV steel, Fluke insulated tools are designed for comfort as well as function. Ergonomic screwdriver handles adapt to the user’s hand to reduce fatigue. They also have a hanging hole and anti-roll handle to make them easier to hang on to. Likewise, Fluke insulated pliers feature four gripping points for a nonslip grip. Many of the pliers have a slim design to make it easier to access wires or connections in tight spaces.