When a building owner wants you to add new loads to an existing service or set of feeders, the first thing you have to determine is whether the existing system will support the new loads. If you have a 600 amp service installed in a facility, can you add another 100 amps of load?

To answer this question you have to ask another one: What is the highest load the system carries now?

Often, local electrical authorities will need to know these answers before they issue permits. You'll also need a comprehensive understanding of today's loading to evaluate the new system, once installed.

To determine the existing equipment's capacity, factor in the incoming conductor size, the ratings of the equipment, and space for new circuits. To determine present loading, you'll need to either precisely calculate the existing loads, or measure them.

Article 220 of the 2005 National Electrical Code offers two methods for determining existing loads and the maximum demand the system is likely to handle.

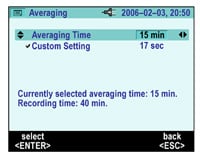

The NEC defines demand as the power consumption of the loads averaged over 15-minute intervals.

The primary NEC method is to find the maximum demand during a one-year period. This only works if you have a year's worth of demand data.

The alternate method is to record the demand over a 30-day period and find the maximum demand. This article describes the 30-day recording method, known as a load study.

The NEC specifies that:

- The highest demand is the highest demand among all feeders.

- Take measurements when the building is occupied.

- Include heating and cooling loads, whichever is larger, or correct to account for these loads.

- Add in any other periodic loads.

As always, local authorities are responsible for interpreting the Code and measurements. Local regulations determine when a load study must be performed, exactly what information is required, and the review process. Make sure you understand your local requirements before you start a load study.

Recording Current and Power with the Fluke 1735

The compact, rugged Fluke 1735 Power Logger is an excellent tool for performing load studies.

- It includes flexible current probes for connecting around multiple conductors or bus bars.

- It has a PC interface and software for downloading measurements to a Windows-based PC and creating professional reports for your electrical plans.

- It measures voltage on three phases and current on three phases and neutral.

- It records multiple parameters that can help determine system load, including voltage, current, frequency, real power (kW), apparent power (kVA), reactive power (kVAR), power factor, and energy (kWh).

- It can also perform power quality measurements.

Performing a load study with the Fluke 1735 takes just five steps:

- Hook up to the feeders or service.

- Set power system parameters.

- Set the recording time.

- Start recording.

- Download and review the measurements.

1. Hook up to the feeders or service

Using proper personal protective equipment, connect the Fluke 1735 to 120V line power and secure the area so no one will tamper with your setup. For a 3-phase wye system there will be eight connections:

- Three phase voltages

- Neutral voltage

- Three phase currents

- Neutral current

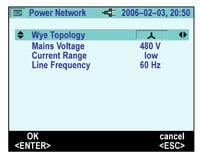

2. Set power system parameters

Set the Network Topology to wye or delta, to match the system you are recording. Verify the nominal voltage (Mains voltage) and line frequency are correct.

3. Set the recording time

Set the Fluke 1735 to 15-minute averaging intervals and a 30-day recording duration.

4. Record the Data

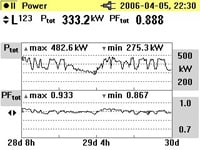

In the W (power) position the Fluke 1735 will record a min, max, and average of these values every 15 minutes:

- Power in Watts for each phase and total

- Reactive Power in VARs for each phase and total

- Apparent Power in VAs for each phase and total

- Power Factor for each phase and average

- Averages of Energy in kWh and Reactive Energy in kVARh

The trend screen will appear and plot a new minimum, maximum and average on the display every fifteen minutes, moving from left to right.

After 30 days, disconnect the Fluke 1735 from the source, take it to your computer, use the serial cable to connect it, and download the data into the Power Log Software included with the unit.

5. Download and review the measurements

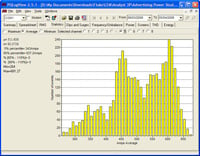

For 30 days of recording, with a measurement every 15-minutes, you will have 2880 sets of measurements. Use Power Log to graph this data, find the maximum current or power on each phase, compare the three phases and report the largest number.

Power Log has a built-in report generator that includes graphs of current and real power, as well as maximum average current on a bar chart. Your report can range from a single current or power number to a full-blown document with graphs and tables. But the ultimate goal is still the same: Get an accurate picture of the system load, help design a safe upgraded system and satisfy electrical authorities.

EXAMPLE: Holmes Electric of Washington performs an average of three load studies a month. To have the study performed, the building owner pays for any labor and a fee for the use of Holmes' power recorder. Among the hundred or so electricians Holmes has in the field, Dave D'Ambrosio and two other electricians perform most of the load studies. Before an estimator can plan for the job, Dave goes out to the customer site and hooks up the recorder to determine the unused capacity of the current system. The data gathered over a month is used to help the estimator determine whether the existing service or feeders can be used as is, modified, replaced, or supplemented. The data is also used in the permit application process, so inspectors can evaluate the electrical plan.

The Fluke 1735: Three-phase Harmonics and Event Recording

The Fluke 1735 is the ideal electrician's tool for recording and analyzing power and energy in commercial and industrial facilities. In addition to recording power parameters for load studies, the Fluke 1735 also:

- Shows voltage and current waveforms on its integrated scope display

- Measures and monitors harmonic distortion caused by electronic loads

- Captures voltage dips and swells caused by load switching and faulty equipment