When was the multimeter invented?

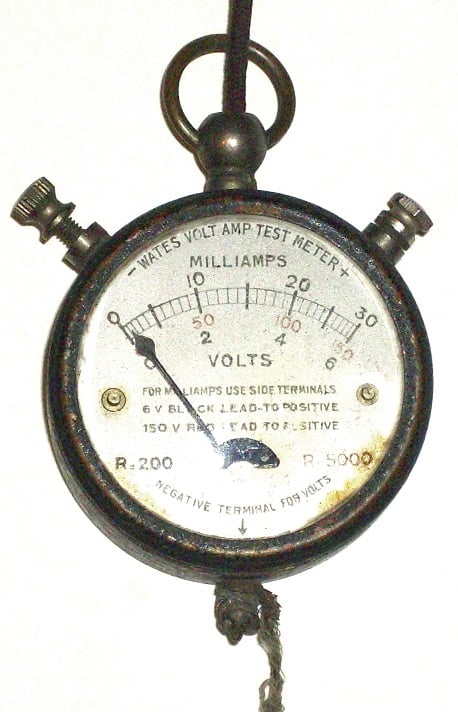

The first device that could be considered a predecessor to the multimeter showed up in 1820 It was a moving-pointer current-detecting device, called a galvanometer. Designed only to detect electrical current and could make a compass needle move, the galvanometer was useful in the lab, but very bulky and delicate, so impractical for fieldwork.

Who invented the first multimeter?

In 1920, a British Post Office engineer, Donald Macadie, is credited with inventing the very first multimeter. The story goes that he was frustrated that he needed to carry a bunch of different tools when working on telecom lines, so he created one tool that could measure amperes, volts, and ohms. Leading to the product being named the AVOmeter.

The first AVOmeter itself was quite clunky compared to the digital multimeters we are used to today. But over the first decade of the multimeter’s life, it shrunk considerably, creating a portable version with additional range and features by the 1930s.

The history of the voltmeter really picks up when Westinghouse introduced the first Universal meter. The original AVOmeters only measured direct current (DC), resistance, and voltage in 13 different ranges. When the “copper oxide instrument rectifier” was made, the meter featured the ability to measure alternating current (AC) and upped the ranges from 13 to 20.

The first digital voltmeter

It wasn’t long before the analog displays were on their way out the door. As the history of the voltmeter moved forward, engineers were trying to make a solid-state digital voltmeter as early as the 1950s. But the technology wouldn’t catch up with the idea until the 1970s. Semiconductors became cheap enough to make the designs practical around this time.

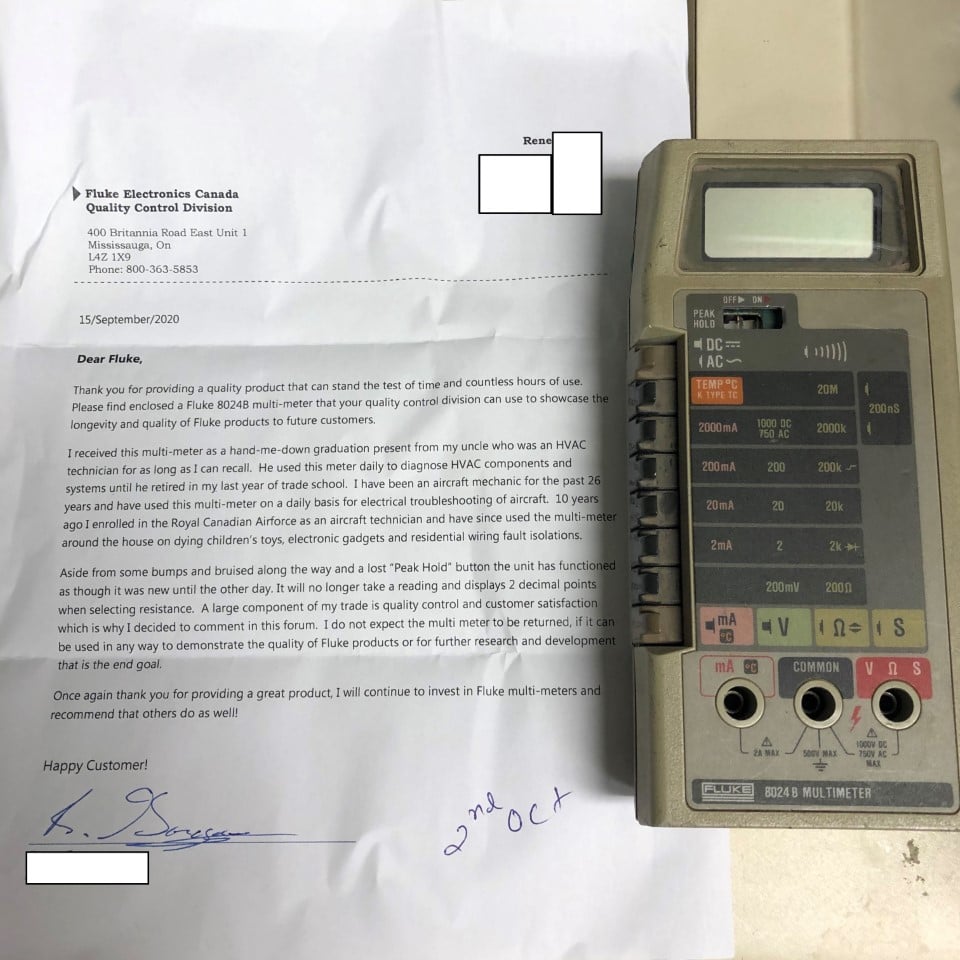

The Fluke 8020A digital multimeter

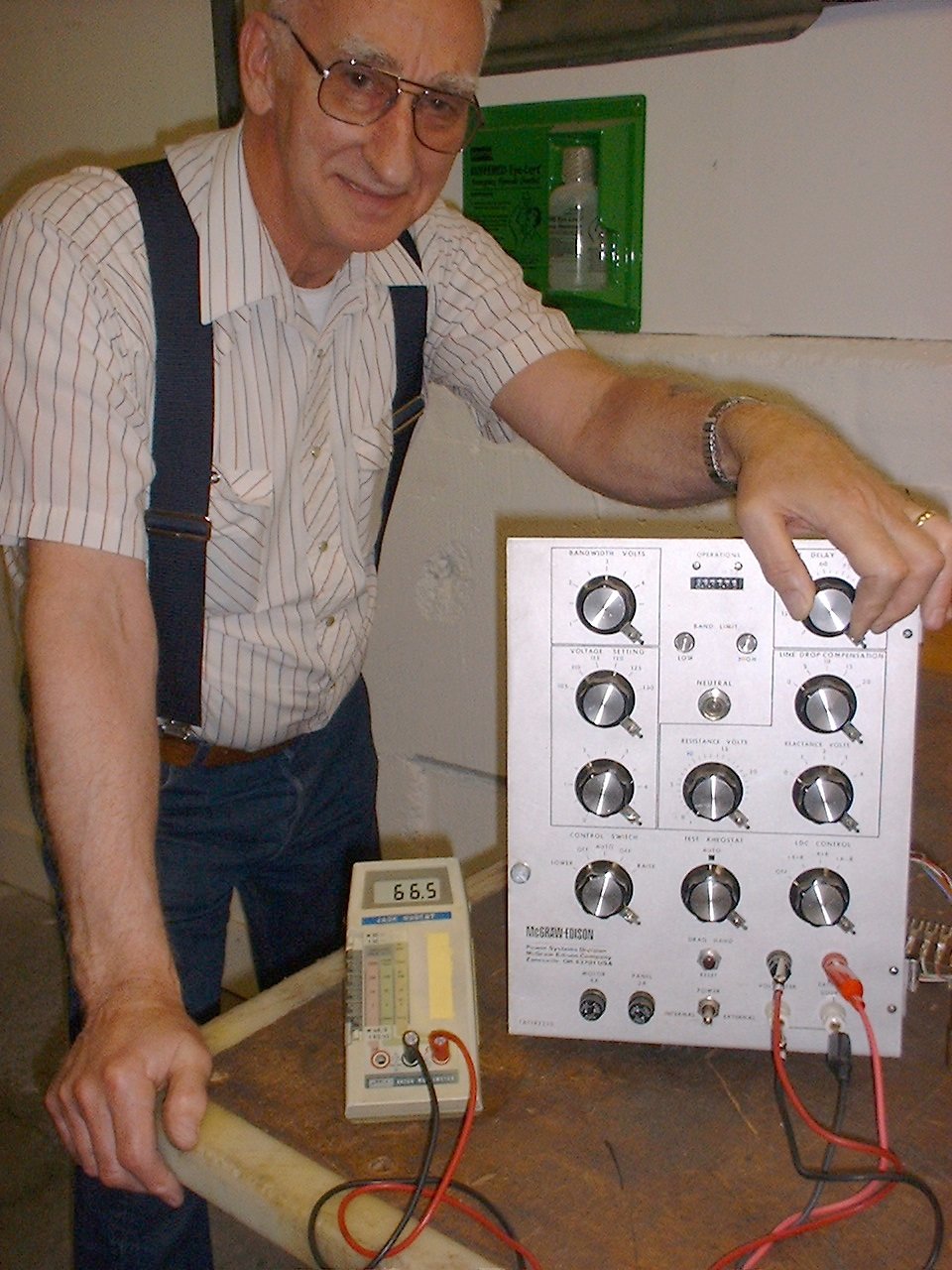

The world’s first successful handheld digital multimeter, or a voltmeter with multimeter features — gave field technicians the troubleshooting capabilities once reserved for lab specialists. The Fluke 8020A digital multimeter made big news in 1977. Traveling in hip pockets and tool bags to the most inaccessible job sites, it proved to be accurate, reliable, easy to use and tough as a rock. And it made the technicians who used it look good.

It changed Fluke’s focus from a maker of bench test instruments into the world leader in handheld electrical test tools. In the decades that followed, the 8020 and its successors would earn their keep in the world’s most challenging workplaces and build incredible loyalty among some of the world’s most demanding technicians, selling more than 1 million units by the 1980s.

The newest and best technology

Born into an era of remarkable technological advances (the first fiber optic phone circuits began service in 1977), the Fluke 8020A used the newest and best electronics technology. That was its secret. Existing components couldn’t deliver the required combination of high performance and low cost, so Fluke designers created a custom, complementary metal oxide semiconductor (CMOS) analog-to-digital converter chip to drive its LCD screen.

The electronics packaged into that little gray case proved to be highly accurate (within 0.25 percent of reading +/- 1 digit), light on battery use, reliable, and durable. If the 8020 impressed the editors (Electronics magazine ran a six-page technical analysis), it made an even bigger splash where it really counts: in the field. After just a day of use, competing meters with an LED display required an overnight recharge; the nine-volt battery in the 8020 lasted through 200 hours of testing. Its LCD display was designed to optimize visibility and response, even at low temperatures.

To protect against high-voltage transients, the 8020 used metal-oxide varistor clamps in combination with input resistors designed to fail as an open circuit to protect the meter and its operator. The little gray meter delivered a mix of performance and price (US $169) that made it an instant hit.

Before the 8020A was retired in 1984, more than 250,000 were sold. And, the 8020B, with five additional models based on the same technology, brought the total to 1 million units by the end of the decade.

40+ Years of Progress: Fluke Multimeter model history

| 1977 | The Fluke 8020A becomes the first successful handheld digital multimeter |

1979 | The Fluke 8020B is added to the lineup of digital multimeters |

1982 | Fluke beings producing the Fluke 8060A and 8062A True-rms Digital Multimeter 300V |

1987 | The Fluke 87 are introduced as part of the digital multimeter line |

1983 | Fluke begins selling the 70 series of digital multimeters, this included the Fluke 77. |

1990 | Fluke introduces the 88, the first handheld meter designed for automotive technicians |

1991 | Fluke begin sales of the Fluke 12 Digital Multimeter |

1996 | Fluke digital multimeters maintain Fluke’s safety advantage. Several models are now certified under new measurement category ratings (CAT III and CAT IV) set by the International Electrotechnical Commission (IEC) |

1997 | The Fluke 77 Series III hit the market |

2000 | Fluke introduces the 180 series of enhanced multifunctional digital multimeters with data logging capability. Companion FlukeView Forms software turns the data into valuable graphical reports |

2004 | Fluke’s new industrial Digital Multimeter, the model 87V, adds a thermometer function and the ability to accurately measure frequency and voltage on adjustable-speed motor drives |

2009 | The Fluke 233 Digital multimeter is released |

2013 | Fluke begins selling the 101 Digital Multimeter |

2014 | Fluke adds Fluke Connect™ in May. Technicians can now wirelessly transmit measurement data from their test tools to their smart phones for secure storage on the cloud and universal team access from the field. |

2015 | The Fluke 279 FC True-RMS Thermal Multimeter combines both thermal imaging and digital multimeter functionality. |

2019 | Fluke introduces the 87V MAX True-RMS Digital Multimeter, the first IP67 rated Fluke multimeter. |

Advances in the multimeter

As more multimeters were released, Fluke multimeters are safer and more capable than ever before.

By 2004, only 27 years after the 8020A was initially introduced, the Fluke 189 digital multimeter delivered more than 20 new features. They included:- The ability to record and time-stamp events to identify intermittents.

- Safety rated for 1000 V CAT III, 600 V CAT IV environments.

- Designed to withstand 8,000- volt peak transients and protect against arc flash.

- Fused to safely measure five times more in-line current.

- Built-in thermometer eliminates the need to carry a separate tool.

- ‘Display hold’ freezes display while measuring.

- Min/Max/Average readings capture intermittents, sags and swells.

- Peak capture function helps find glitches and transients without a scope.

- Faster auto ranging and integral holster.

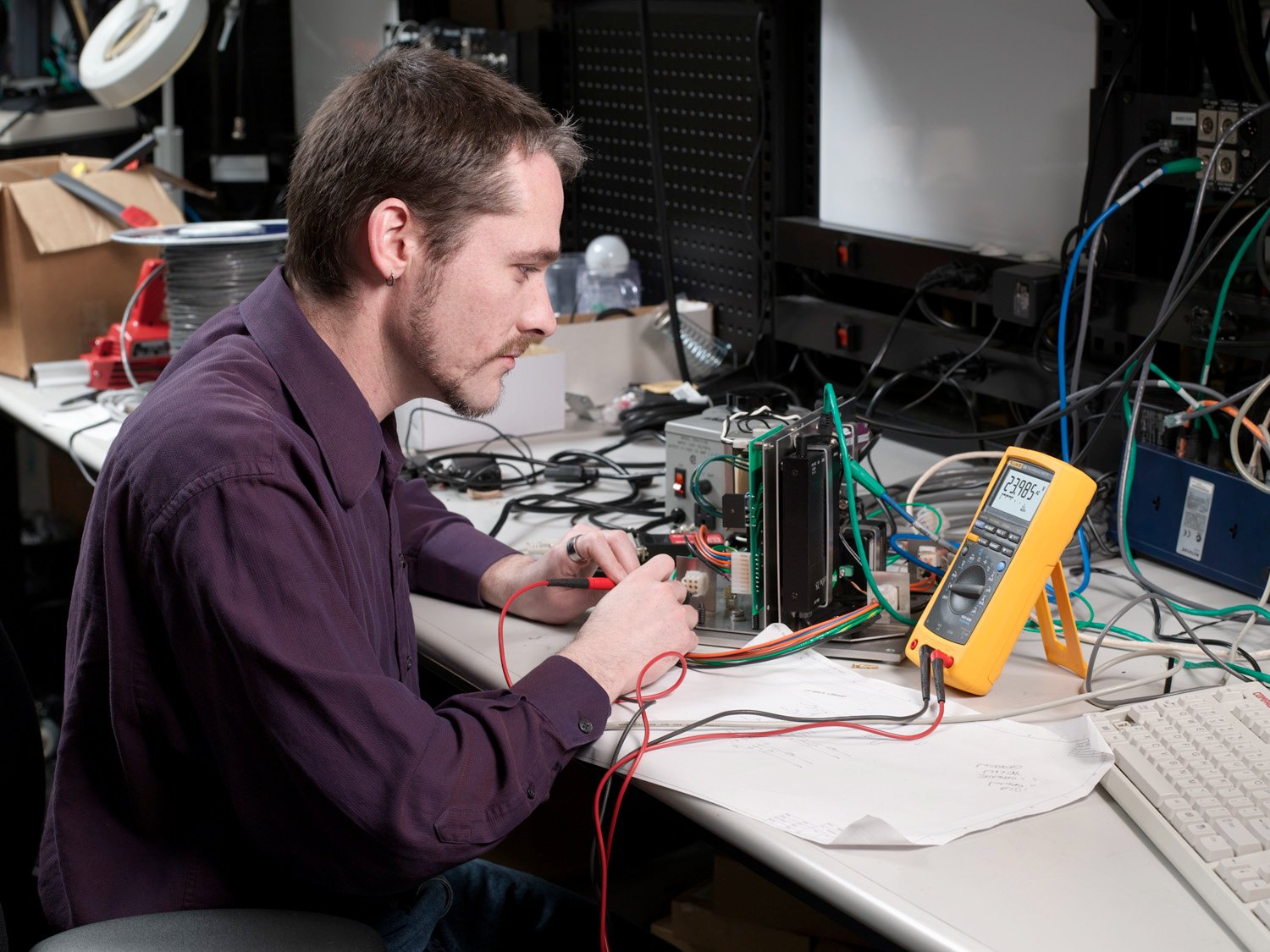

Planning the meters of tomorrow

Improved safety and ruggedness

The concern for safety among employers, unions and technicians is only going to increase. Today’s Fluke tools meet or exceed the toughest relevant safety standards and bear the marks of U.S. and international testing labs to prove it. As standards become more rigorous, so will Fluke tools.

Ergonomics to fit the environment

A tool that’s hard to use soon slips to the bottom of the toolbox. But techs keep their “Flukes” on top, thanks to advances in the products design. Digital multimeters are smaller than ever before. These tools fit securely in the palm of your hand like the Fluke 107.

Simplified user interface

Designers are constantly incorporating new features without adding extra complications. In the 87V digital multimeter, Fluke reassigned an existing button to include both temperature and an adjustable speed motor drive feature.

Non-contact measurement

The introduction of Fluke’s FieldSense technology has been included in electrical testers and clamp meters, making it easier to make voltage and current measurements without touching a live wire.

Greater reliability

Technicians can be confident that reliability will remain a defining Fluke advantage. You can be so confident of this; Fluke engineers have to stock up on repair parts when designing tools. They have to look ahead and estimate how long that tool will remain in service, and make a “lifetime buy” of repair parts to keep users supplied through the tool’s anticipated service life.

Expanded capabilities

New Fluke meters do more. It’s that simple. Whether it’s increased safety, added capabilities, or higher performance, new generations of Fluke tools will always include these. We are continually investing in developing new and better tools to suit the needs of a changing electrical and industrial world.