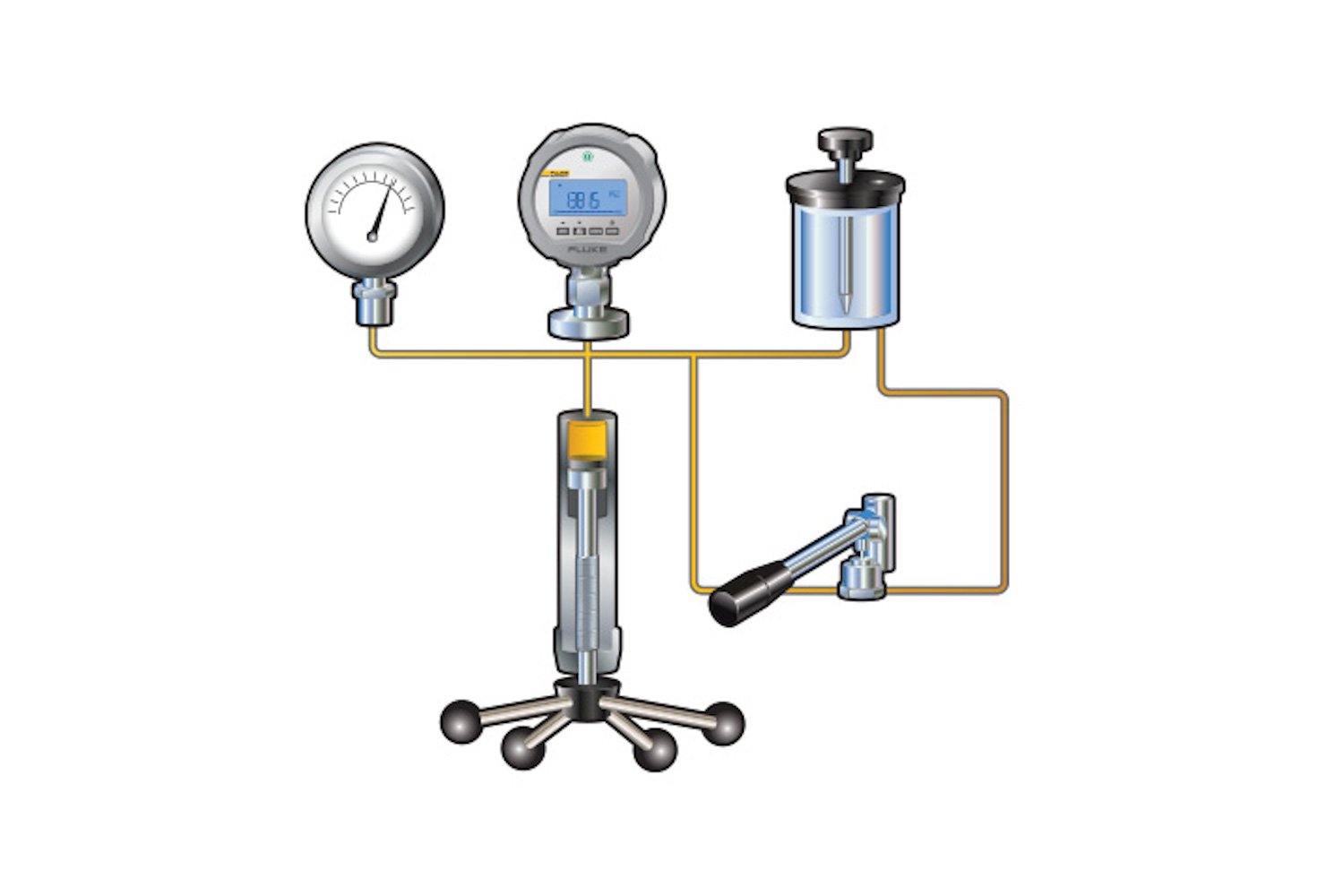

A pressure comparator is a convenient instrument for bench pressure calibration. Bench calibrations are performed to maintain reference conditions and to obtain the lowest possible uncertainties. The bench is also a convenient place to inspect, adjust, and repair the devices under test.

How to perform the test

- The pressure gauge should be mounted in the same orientation (vertical or horizontal) as in the process. An angle adapter such as the P5543 may be used.

- The reference pressure gauge (2700G) should be mounted such that the display is easily seen.

- For hydraulic comparators prime the fluid with the priming pump, to remove any bubbles.

- Measurement points should be distributed uniformly over the calibration range. Conveniently source pressure with a manual pump up to 300 psi, after that use an external pressure supply.

- For gas comparators use the fine needle valve or fine adjustment screw press to precisely meter the pressure.

- With hydraulic models use the screw press to source and fine adjust the pressure.

- The source pressure can be adjusted until the device under test is reading a nominal pressure or until the reference gauge reads the nominal pressure.